Vacuum Casting Parts For Automation Equipment

- SHD Precision Tech

- Shenzhen

- 1 week

- 5000 pcs / month

Low cost for silicone molds

Fast delivery

A wide selection of materials

High precision and fine details

Excellent surface finish

Main Parameter:

Mold Base Materials | P20/718/738/NAK80/S136 and others |

Cavity | Single/ Multi |

Runner | Hot / Cold |

Mold Life/Usage | 300,000~1,000,000 shots |

Plastic Materials | ABS, PC, PMMA, PP, PBT, PE, Nylon and others |

Design software | UG, Pro-E, Solid works, Auto CAD and others |

Tolerance | 0.01mm |

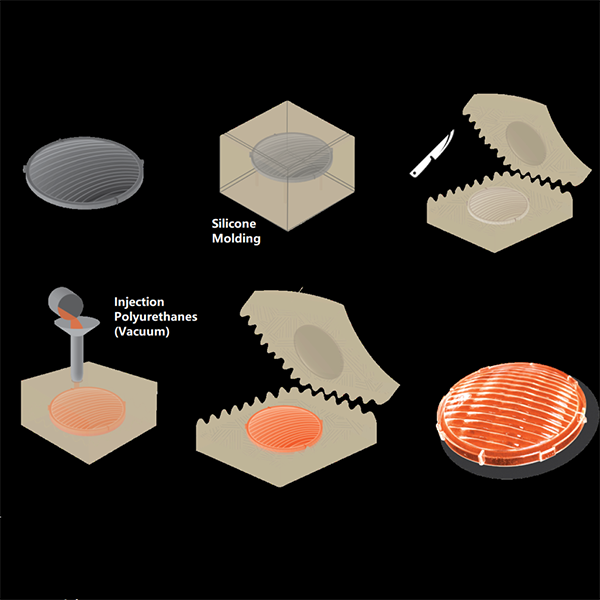

What Is Vacuum Casting?

Vacuum casting (also known as urethane casting) is an economical alternative to low-volume injection molding of plastic parts and can be used to closely simulate final molded parts or finished products. Generally, molds are made from silicone rubber and use CNC machining or SLA part as a master pattern. These molds duplicate intricate details and textures and give consistent finishes from one part to the next. You can get production-like results including mechanical traits, wall thickness, colors, and surface finishes.