5-Axis CNC Machining

- SHD Precision Tech

- Shenzhen

- 1 week

- depends on the product

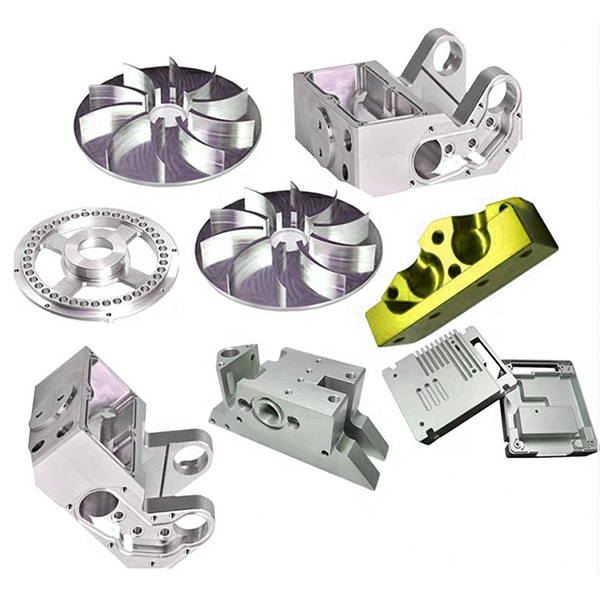

With high-quality 5-axis CNC machines, we offer you high-quality parts, competitive pricing, and a fast lead time.

Benefits Of 5-Axis CNC Machining

The ability of this type of machining to work on 5 different faces of a workpiece simultaneously offers several advantages to many industries. These benefits range from cost efficiency to effective machining. Here are the major benefits of 5 Axis CNC Machining.

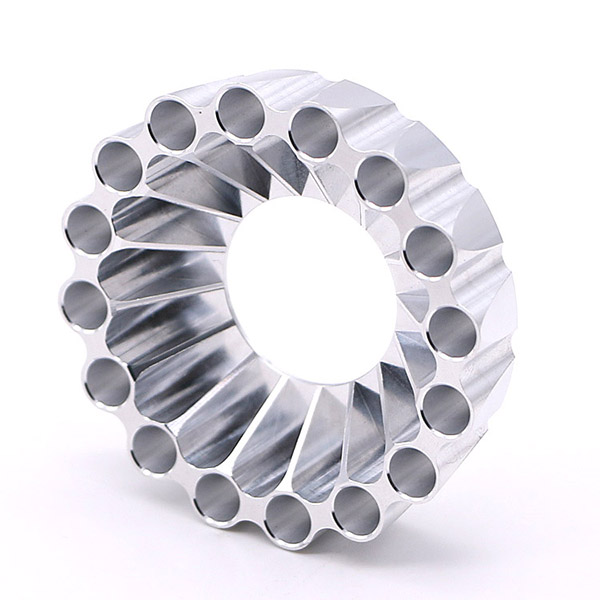

Machine Complex Shapes

The additional axis added to this machine makes machining designs and geometries with high complexity easy. Also, machining difficult angles and arcs, which is previously achievable using multiple special fixtures, has become feasible with 5-axis CNC machines. In addition, the ability of this machine to rotate parts during a single operation makes it possible to achieve desired geometries with the need for complex machines or fixtures.

High Precision and Repeatability

Manual machining operations require extra setups for optimal machining. But these extra setups often introduce design variability and error, causing machinists to lose alignment during machining. However, 5-axis CNC milling involves minimal setups, eliminating the possibility of errors while improving accuracy.

Also, with most 5-axis CNC machines used by machinists today, there is no need for manually repositioning the workpiece during machining. This guarantees improved machining tolerances. What’s more, using shorter cutting tools in some machine configurations improves tool lifespan while ensuring repeatability.

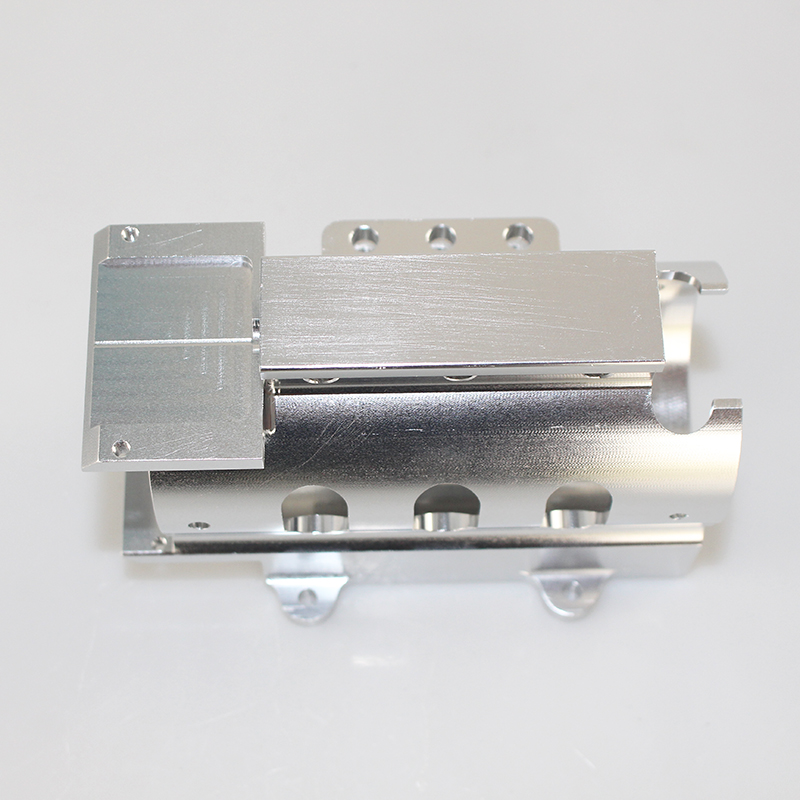

Effective Setup Operations

The process of setting up a 5-axis CNC machine is relatively easier than setting up a 3-axis machine. The reason is that 5-axis CNC machines allow work on five surfaces simultaneously. Moreover, 5-axis machines enable the machining of contoured parts with a single structure. However, for conventional 3-axis machines, several setups are necessary to work on several faces.

Quality Surface Finish

The surface finish with a 5-axis CNC machine is smoother due to the presence of additional axes. These additional axes bring the workpiece closer to the cutting tool, making it easier to achieve desired shapes. It also allows the use of shorter cutting tools for machining.

With shorter cutting tools, there is little to no vibration, which reduces the incidence of marks on the surface of finished products. Moreover, there is an improvement in spindle utilization for machining angled surfaces when employing the vertical machining process.

High Production Efficiency

The 5-axis machining can effectively reduce the machining time and auxiliary time of the parts. It has a large range of spindle speed and feeds rage, allowing the machine to perform a powerful large cutting capacity. 5-axis CNC is entering an era of high-speed machining. The rapid movement and positioning of 5-axis machining and high-speed cutting processing reduce the turnaround time for semi-finished products.