Vacuum Casting Parts For Industrial Design

- SHD Precision Tech

- Shenzhen

- 1 week

- 5000 pcs / month

Low cost for silicone molds

Fast delivery

A wide selection of materials

High precision and fine details

Excellent surface finish

Main Parameter:

Mold Base Materials | P20/718/738/NAK80/S136 and others |

Cavity | Single/ Multi |

Runner | Hot / Cold |

Mold Life/Usage | 300,000~1,000,000 shots |

Plastic Materials | ABS, PC, PMMA, PP, PBT, PE, Nylon and others |

Design software | UG, Pro-E, Solid works, Auto CAD and others |

Tolerance | 0.01mm |

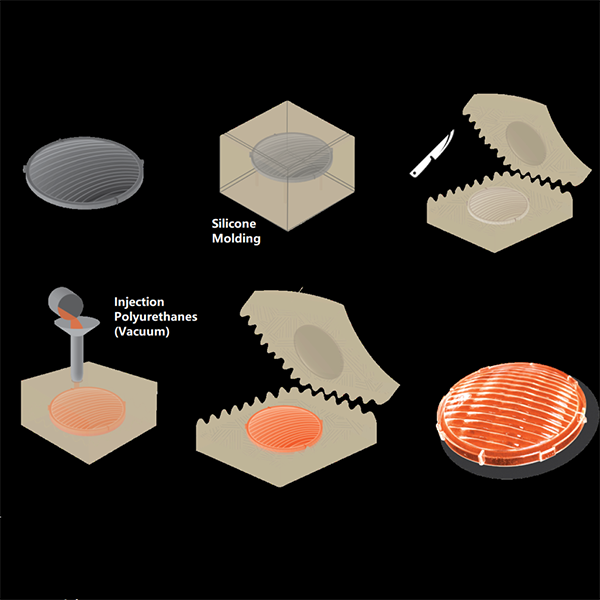

How Vacuum Casting Works

The vacuum casting process has three steps: master pattern, molding, and casting.

Step 1. Master Pattern Making

The quality of the casting urethane parts is determined by the quality of the master pattern, which is best machined by CNC when you need to hold tight tolerance, glossy finish, or even optically clear. In addition, we also will consider making the master by SLA for those parts with more complex shapes and structures.

We can paint parts surface for texture or satin effect to simulate the final mold texture of the product. The silicone molds will copy the details and textures from the original master, so the cast urethane parts will come out the same as the master model without any extra finish on the surface.