Vacuum Casting

- SHD Precision Tech

- Shenzhen

- 1 week

- depends on the product

Low cost for silicone molds

Fast delivery

A wide selection of materials

High precision and fine details

Excellent surface finish

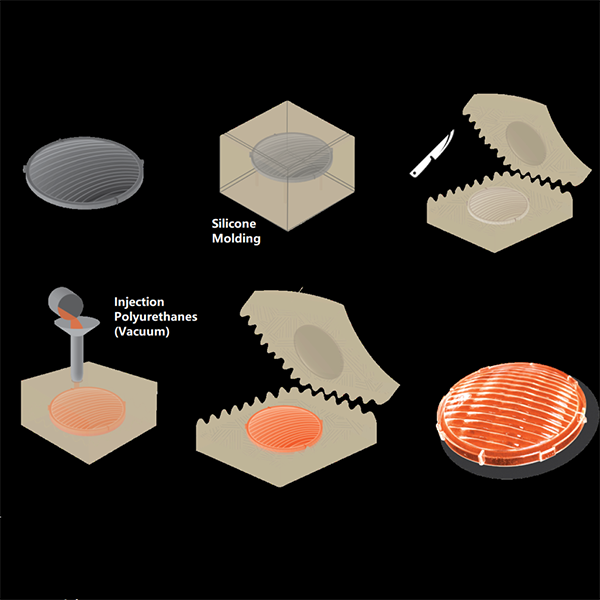

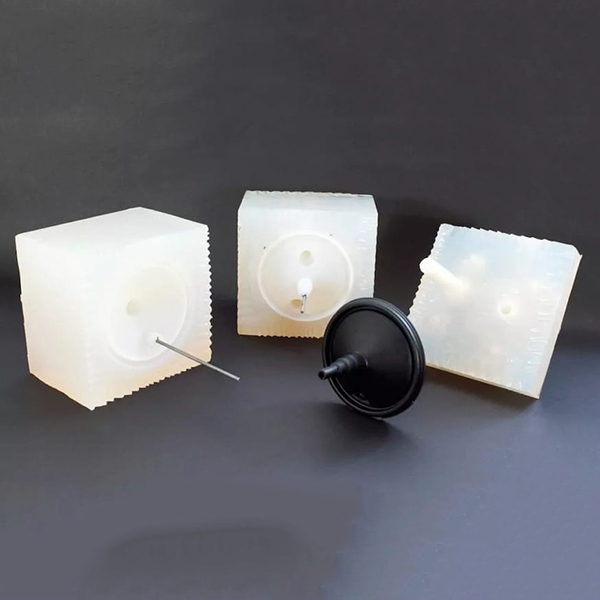

Technical Guide for Vacuum Casting

Standard accuracy | Standard tolerance on ±0.15mm/100mm, with the highest precision able to reach ±0.05 mm. |

Maximum part dimensions | The vacuum equipment can hold 2.0M*1.2M*1.0M mold specifications. |

Minimum wall thickness | The minimum wall thickness is 0.5mm, the best is 1.5mm~2.5mm to ensure the mold is filled properly. |

Lifetime of the silicone mold | Typical quantities up to 20-25 copies per mold. If the part requires high quality such as clear or complex structures, in typical quantities one mold can only make 12 or even 10 casting parts. |

Standard lead time | Up to 50 copies can be produced in 7 to 10 days, depending on the mold’s complexity and volumes. |

Surface textures and other functions | Colored, textured, painted, coated, clear polished, insert, and over-molding. |

Vacuum Casting Materials

Urethane resins are polymers with a wide range of properties and use. WayKen offers various urethane materials to meet your applications, including Hei-Cast from Japan and Axson from France. Materials with certain properties are similar to engineering production plastics, such as ABS, PMMA, PC, PP, PA, and so on. Casting parts can be varied from transparent, translucent to colored, and from soft rubber to hard plastic. Various materials contain those impact-resistant, high-temperature resistant (120℃) or fire-resistant (UL94-V0), glass-filled resins, and different hardness silicone.

Vacuum casting is a great method to manufacture low-volume production runs for functional prototypes and plastic parts and helps you strike the right balance between high-quality, end-use parts and production lead-time.