Vacuum Casting Parts For Precise Mechanical System

- SHD Precision Tech

- Shenzhen

- 1 week

- 5000 pcs / month

Low cost for silicone molds

Fast delivery

A wide selection of materials

High precision and fine details

Excellent surface finish

Main Parameter:

Mold Base Materials | P20/718/738/NAK80/S136 and others |

Cavity | Single/ Multi |

Runner | Hot / Cold |

Mold Life/Usage | 300,000~1,000,000 shots |

Plastic Materials | ABS, PC, PMMA, PP, PBT, PE, Nylon and others |

Design software | UG, Pro-E, Solid works, Auto CAD and others |

Tolerance | 0.01mm |

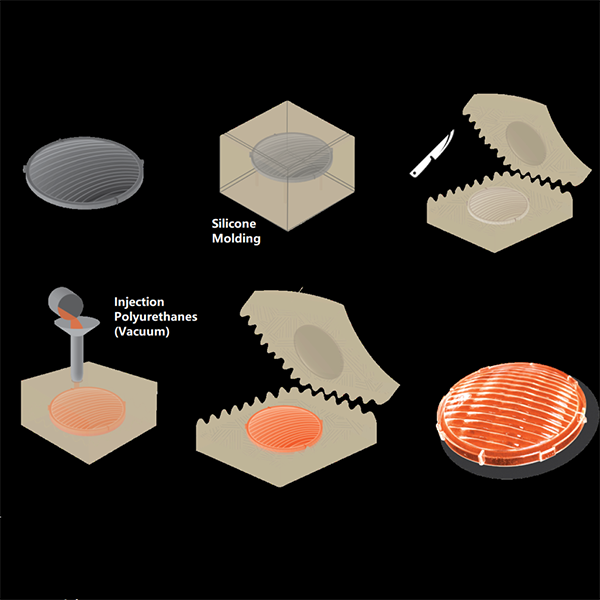

How Vacuum Casting Works

The vacuum casting process has three steps: master pattern, molding, and casting.

Step 2. Silicone Mold Making

Casting molds are made from liquid silicone resin, also known as RTV molds. The chemical stability, self-releasing properties and flexibility of silicone rubber are excellent in that it gives minimal shrinkage and carries fine details effectively from master to mold. The mold making process starts as follows:

Paste tape in a flat position around the master, so that it is easy to open the mold later, which will also become the parting surface of the final mold.

The master model is suspended in a casting box and placed with plastic rods to set gates and vents.

Liquid silicone is poured around the master and removal all air, creating a vacuum chamber to ensure the master mold is free of air bubbles. Then is cured liquid material in an oven, at a temperature of 40℃. It generally takes 8-16 hours depending on the volume of the mold.

Once the silicone rubber is cured, cut open the casting box, remove the master model from the silicone to form an empty cavity, and the silicone mold is made.