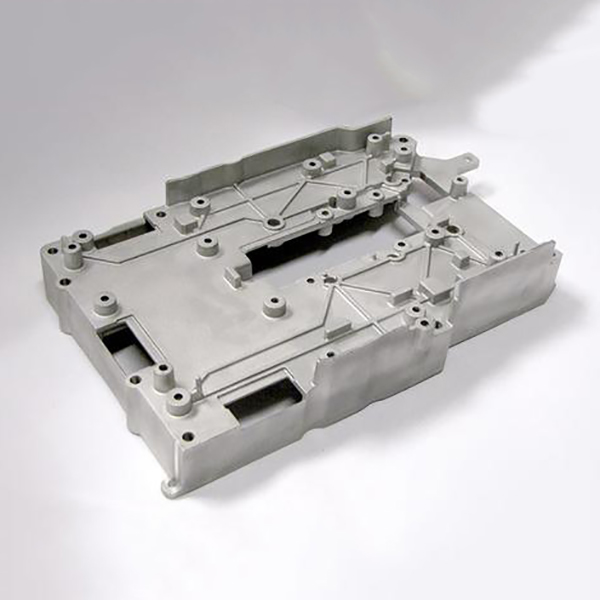

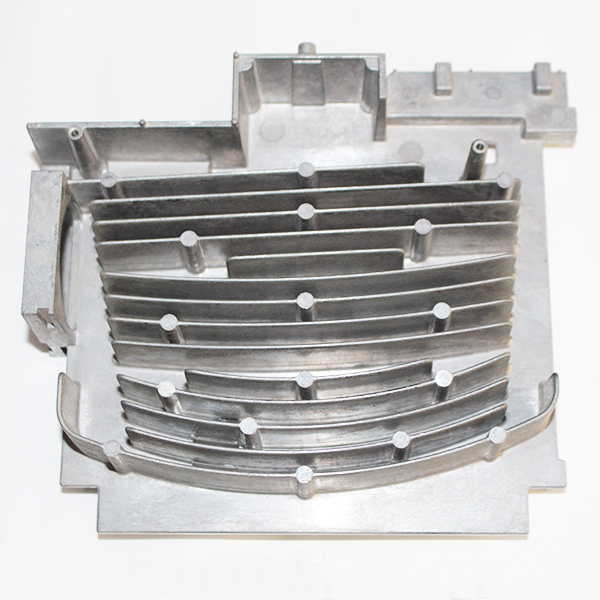

Die Casting Parts For Robots

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- depends on the product

Variable wall thicknesses

Tighter tolerances

Fewer steps from raw material to finished part

Fast production cycle times

Reduction in material scrap

Long tool life, especially for zinc and magnesium

Main Parameter:

Product Type | Die Casting Service | |||

Materials | Aluminum alloy, zinc alloy, magnesium alloy, brass and etc. | |||

Surface Treatment | Anodizing, Brushing, Galvanized, Laser engraving, Silk printing, Polishing, Powder coating, and etc. | |||

Tolerance | ±0.01mm, 100% QC quality inspection before delivery, provide quality inspection form; | |||

Testing equipment | CMM; Tool microscope; Multi-joint arm; Automatic height gauge; Manual height gauge; Dial gauge ; Marble platform; Roughness measurement. | |||

File Formats | STP/ STEP/AutoCAD(DXF,DWG),PDF,TIF etc. | |||

Applications of Die Casting Parts

The die casting process is applicable in creating different parts and components that are truly unique and highly functional. Below are a few applications of the process:

Manufacture of consumer and industrial products

The process is suitable for making consumer products such as sink faucets, compressor pistons, connector rods, heat sinks, etc.

Manufacture of automotive products

The process is used in making gear, cylinders, small engines, gladhands, transfer cases and more specific parts applicable in the automotive industry.

Manufacture of aerospace parts

Die casting is a cost-effective solution to produce light but superior metal components that meet high-quality standards of the aerospace industry.