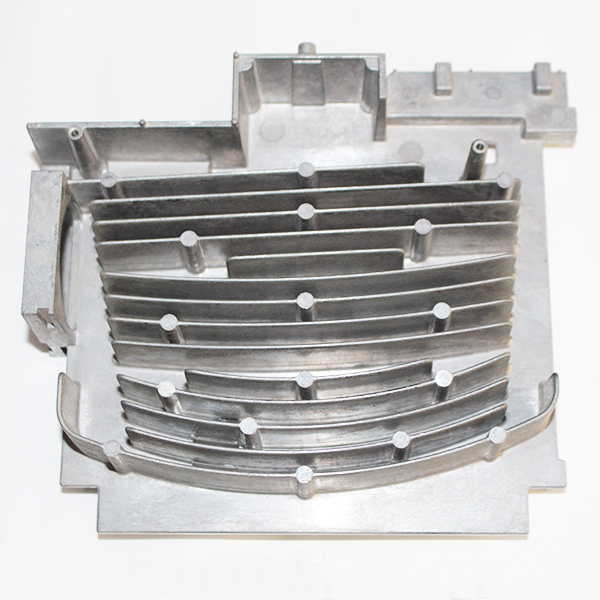

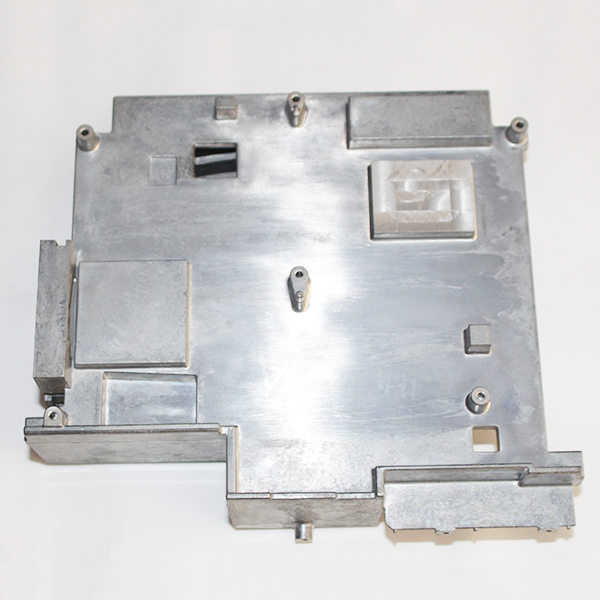

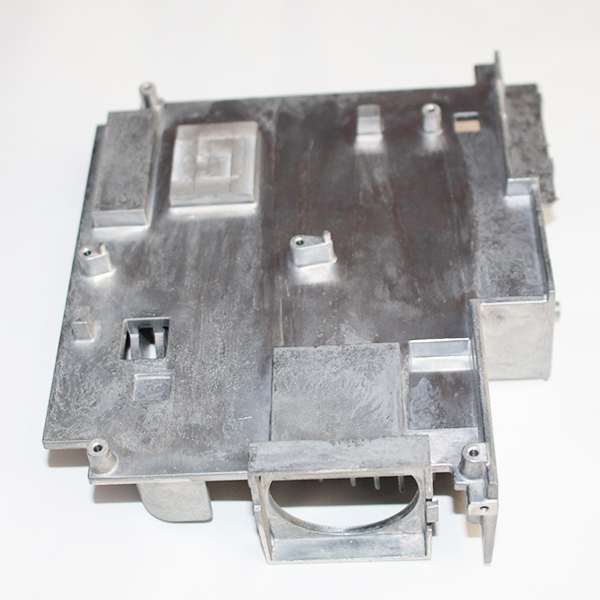

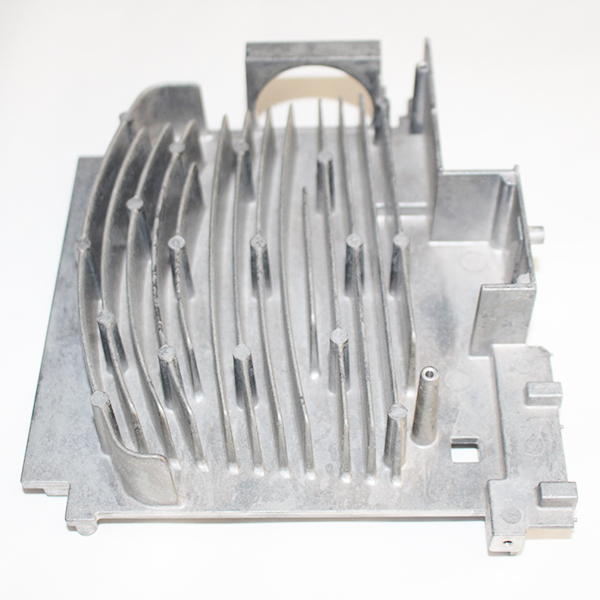

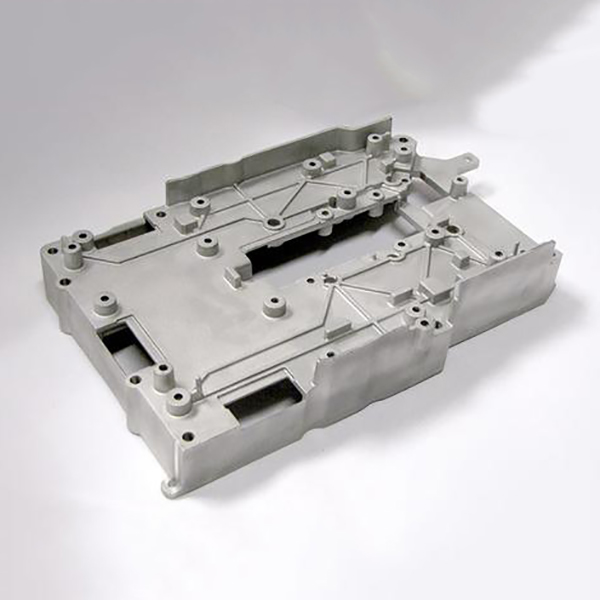

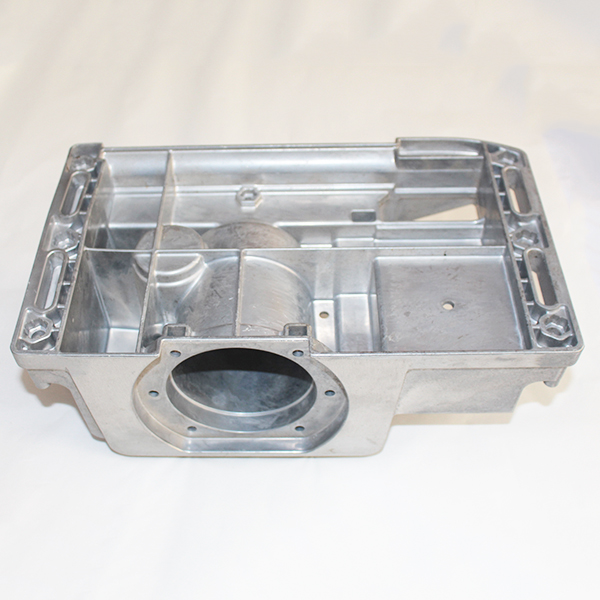

Compound Die Casting Parts Aluminium Alloy

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- depends on the product

Variable wall thicknesses

Tighter tolerances

Fewer steps from raw material to finished part

Fast production cycle times

Reduction in material scrap

Long tool life, especially for zinc and magnesium

Main Parameter:

Product Type | Die Casting Service | |||

Materials | Aluminum alloy, zinc alloy, magnesium alloy, brass and etc. | |||

Surface Treatment | Anodizing, Brushing, Galvanized, Laser engraving, Silk printing, Polishing, Powder coating, and etc. | |||

Tolerance | ±0.01mm, 100% QC quality inspection before delivery, provide quality inspection form; | |||

Testing equipment | CMM; Tool microscope; Multi-joint arm; Automatic height gauge; Manual height gauge; Dial gauge ; Marble platform; Roughness measurement. | |||

File Formats | STP/ STEP/AutoCAD(DXF,DWG),PDF,TIF etc. | |||

Die Casting Alloys

Most alloys used in die casting are non-ferrous with strong mechanical properties. The non-ferrous moiety is responsible for the low melting point in agreement with the strong mechanical properties. The type of properties needed depends on the material being worked on. Consequently, there is no limitation when choosing a material. However, below are several popular alloys:

Aluminum Alloys

Aluminum alloys have unique properties, making them applicable in making a wide range of products. On the one hand, aluminum alloy 380.0 is the most common material in die casting due to its unique properties. Other alloys include Aluminum Alloys 360, 390, and 413. You can use aluminum alloys because of the following:

High operating temperatures

Outstanding corrosion resistance

Lightweight

Very good strength and hardness

Good stiffness and strength-to-weight ratio

Excellent EMI and RFI shielding properties

Excellent thermal conductivity

High electrical conductivity

Good finishing characteristics

Full recyclability

Withstand the highest operating temperatures of all the diecast alloys

Corrosion-resistance

It retains high dimensional stability with thin walls

Zinc Alloys

Zinc alloys have incredible strength, toughness, firmness, performance, and cost-effectiveness. As a result, they are an important part of the die casting process, with properties rivaling and exceeding other alloys such as aluminum, magnesium, and bronze.

There are many alloys of zinc you can use. However, the common die casting zinc materials are Zamak #2, #3, #5, #7, ZA8 and ZA27, known for the following properties:

Improved Castability

Shortened Cycle Time

Extended Die Life

Ideal Mechanical Qualities

Magnesium Alloys

Magnesium is another material used for die casting. It has many alloys, but the most common one is the AZ91D, known for its toughness, durability, lightweight and good castability. It is 75% lighter than steel and 33% lighter than aluminum without a loss in strength. Most enthusiasts prefer magnesium as it is better for complex casting with tight tolerances and it has better corrosion resistance.

Other Alloys

Other alloys suitable for making die casting parts include Bronze, Brass, lead, and tin.

Tin is the first material used in die casting due to its high fluidity. It has a low melting point, and it leaves little or no wear on the molds.

Bronze (white bronze) is the right die cast material used in the jewelry industry. It has a similar color to white gold and stainless steel alloys but is suitable for die casting due to its low melting point.