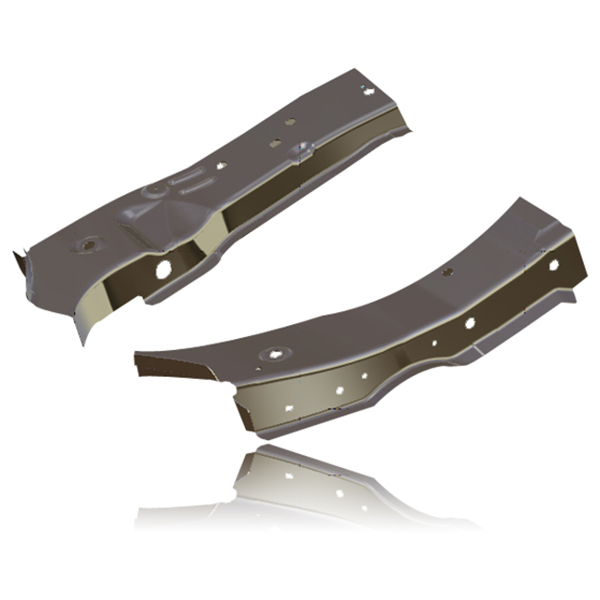

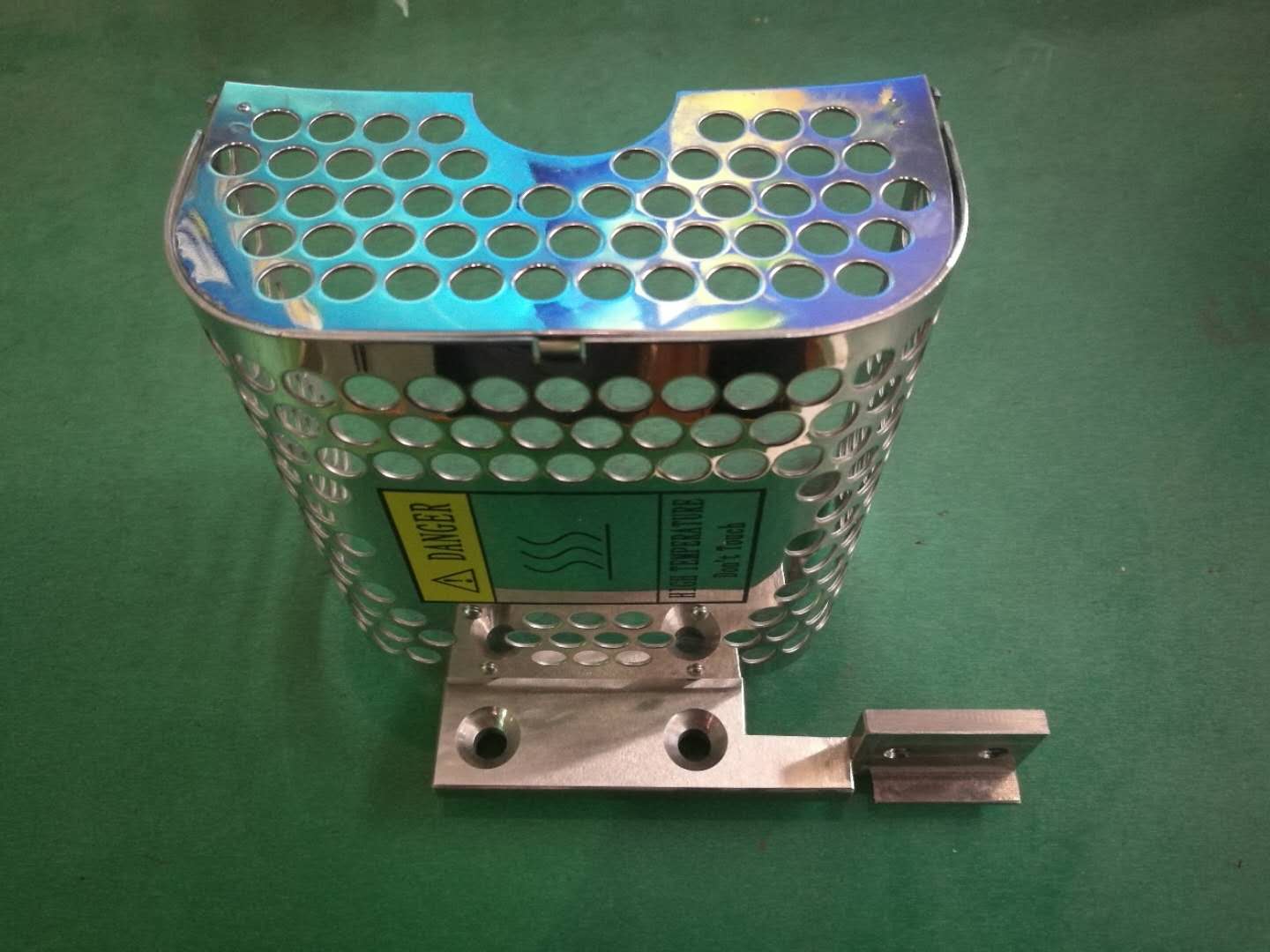

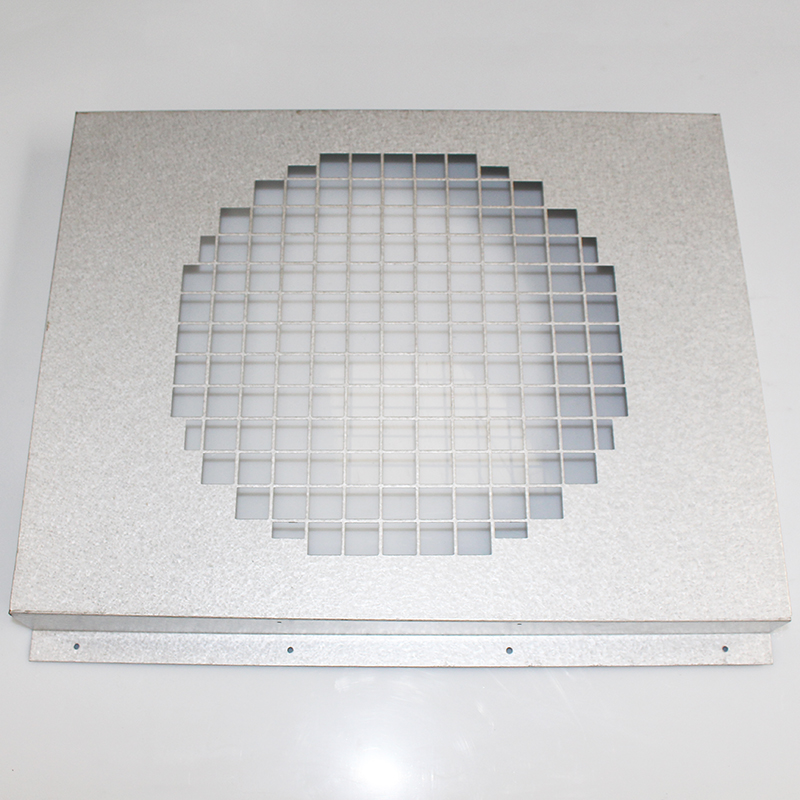

Special Designed Sheet Metal Parts

- SHD Precision Tech

- Shenzhen

- 1 Week

- 50000 pcs / Month

One-stop Tooling Solutions.

Cost-effective and Fast Turnaround.

Free DFM for Excellent Results

Product feature:

Product type | Sheet metal part |

Material | Stainless steel, cold rolled steel or aluminum alloy |

Color | Customized as per clients' requirements |

Surface treatment | Wiredrawing, powder coating |

OEM | Support |

Package | Carton or wooden case |

What is Sheet Metal Forming?

Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part. This process is also known as blanking.

Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. Sheet metal forming can bend the part in multiple directions, creating simple parts such as brackets up to highly complex geometries which may require custom die tools. Once the tools are in place, making subsequent sheet parts in production is very cost-effective. This makes sheet metal fabrication and forming ideal for low to high volume production.