Sheet Metal Fabrication

- SHD Precision Tech

- Shenzhen

- 1 Week

- depends on the product

One-stop Tooling Solutions.

Cost-effective and Fast Turnaround.

Free DFM for Excellent Results

What Is Sheet Metal Fabrication?

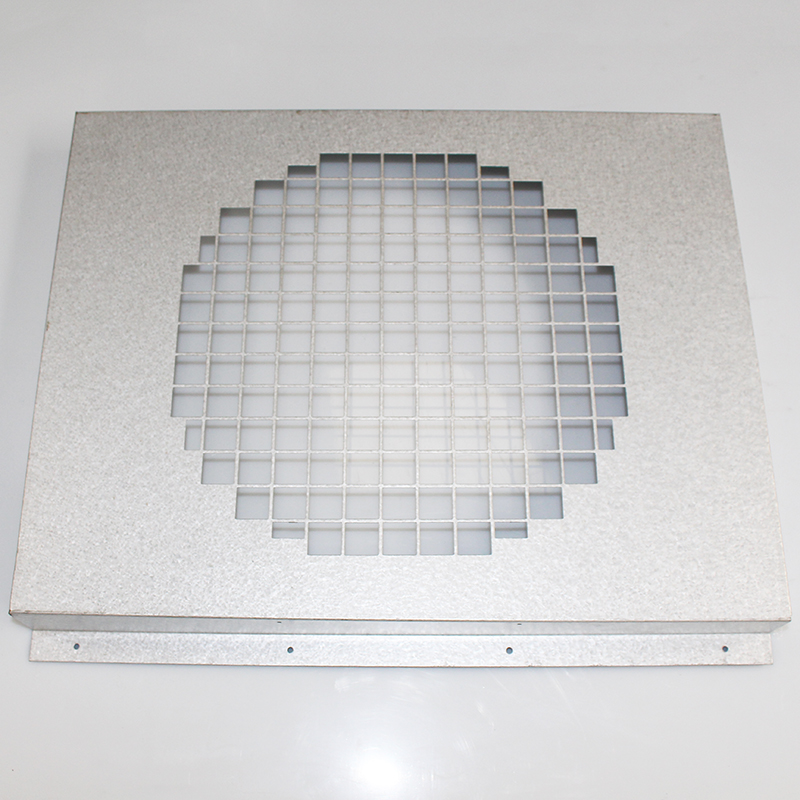

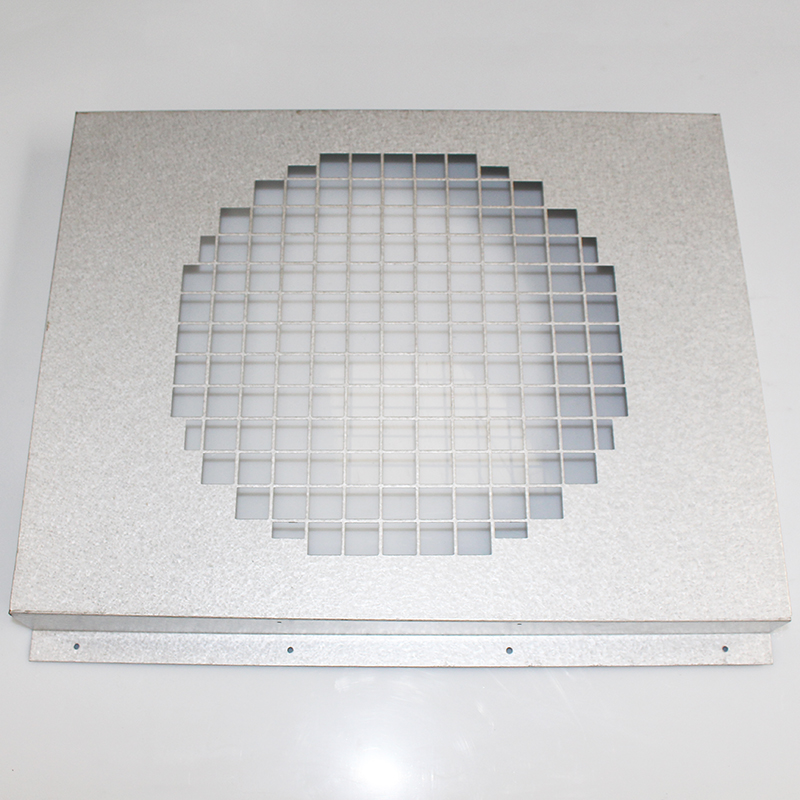

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

SHEET METAL PARTS AND PROTOTYPES

Many different metals and alloys can be used for creating parts and prototypes in the sheet metal fabrication process. Depending on the design and application (industrial uses, decorative applications, etc.), parts can be made using metals such as: Aluminum, Brass, Copper, Gold, Nickel, Silver, Stainless Steel, Tin, Titanium. The metals are formed either into flat sheets or coils, both varying in thickness.

WHAT TYPES OF SHEET METAL CAN BE PRODUCED?

METAL FOILS | Foils are metals pressed into very thin sheets which bend and tear easily. Foils are most often used in household applications – such as household aluminum foil. Malleable metals make the best foils; they can be pressed into equally thin sheets more easily. |

METAL LEAF | Metal leaf is an extremely thin layer of metal – sometimes only a few atoms thick. Due to the incredibly thin nature of metal leaf, special brushes must be used to apply it. Metal leaf is generally made for decorative purposes using brass, copper, gold, palladium, platinum, and silver. |

METAL PLAT | Metal formed into sheets over 6mm thick is referred to as metal plate. Metal plate can be cut, bent, rolled, stamped, hemmed, etched, embossed, and much more to achieve your desired effect. |

METAL COILS | Metal coils are produced to specification by taking larger coils or sheets of metal and pressing them into coils of exact thickness. Metal coils have numerous applications across a multitude of industries. |

MANUFACTURING WITH SHEET METAL

Sheet metal has an incredible number of applications for nearly every industry. Sheet metals can be sourced in nearly any thickness required, then formed into complex shapes or cut with incredible precision. Conductive capabilities, corrosion resistance, heat tolerance and more are all reasons to consider sheet metal in producing your next part or prototype.

Metals can be manipulated to accommodate your needs using many different manufacturing processes. The design, requirements, and materials will all factor in determining which sheet metal manufacturing process is best suited for your project. Some of the more-common processes include:

Bending the metals into shape

Hemming to reinforce metal edges

Laser cutting for precision designs

Punching designs directly from a sheet of metal

Seaming sheets of metal together creating a joint

Stamping images or designs into metals

Water-jet cutting, using jets of highly-pressurized water for a controlled erosion