Rapid Tooling Parts For Medical Device

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- 5000 pcs / month

One-stop Tooling Solutions

Cost-effective and Fast Turnaround

Free DFM for Excellent Results

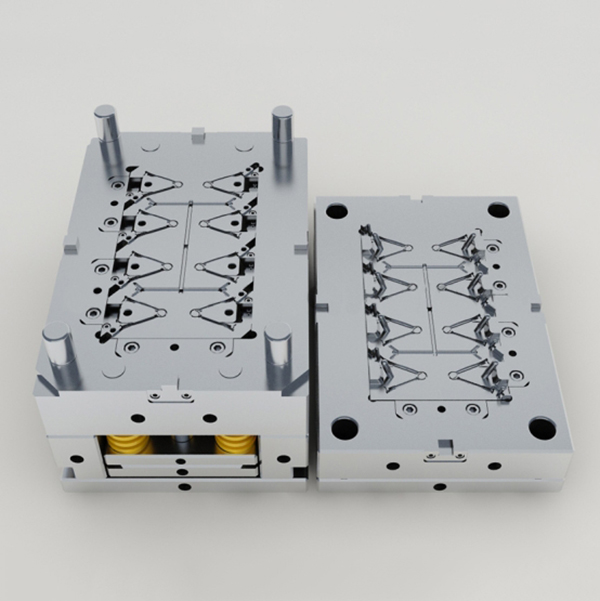

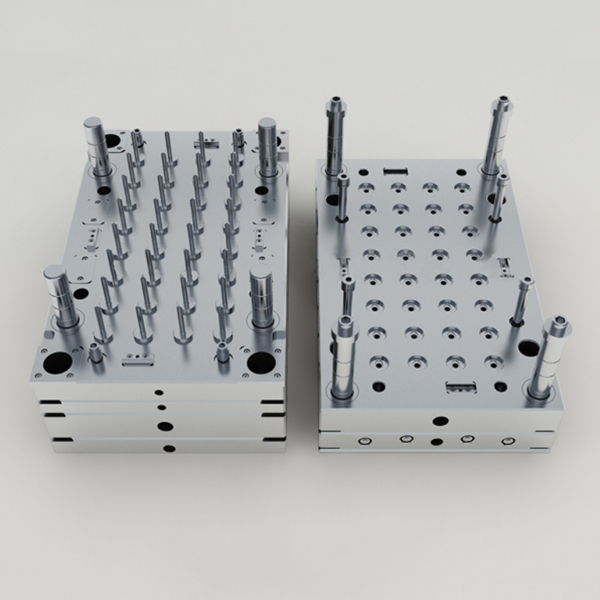

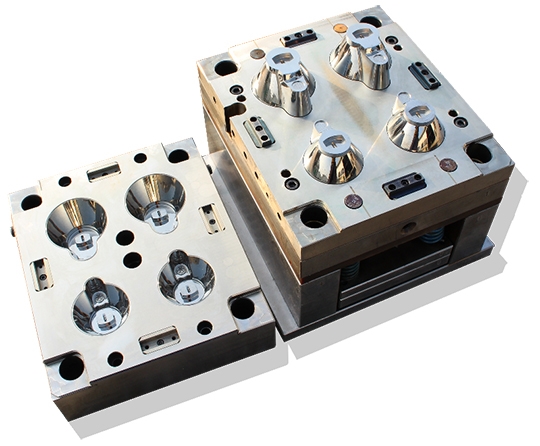

Rapid Tooling Services

Get high-quality rapid tooling solutions for your prototypes and low-volume productions. SHD combines engineering capabilities with advanced technology to quickly create injection mold tooling at competitive prices.

Why Choose SHD's Rapid Tooling Services?

High Efficiency and Quality

Competitive Prices

Design for Manufacturing Support

Timely Delivery

Reliable Process

One-stop Machining Capabilities

Rapid Tooling & Prototype Injection Molding Services

PART IV:How Does Injection Mold Tooling Work?

Need as few as 100 or more than 100,000 injection molded parts? Injection mold tooling is a cost-effective solution for your product development process.

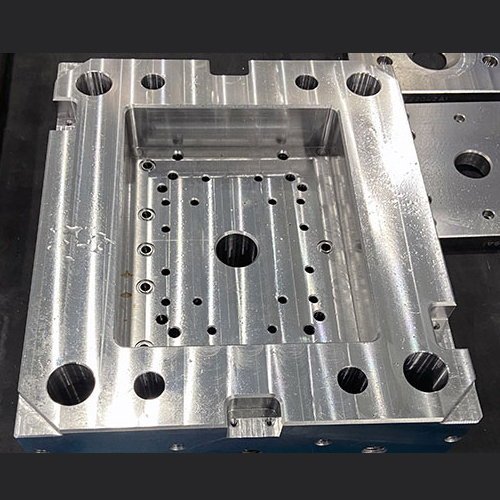

Optimized Design for Manufacturability (DFM)

We incorporate design for manufacturability (DFM) into every aspect of the injection molding process, from part design to injection mold tooling, materials selection, and machining process. No need to wait until production to reveal issues with the design. Our optimized design for manufacturability ensures cost-effective tooling and molding of parts to scale.