Rapid Tooling

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- 5000 pcs / month

One-stop Tooling Solutions

Cost-effective and Fast Turnaround

Free DFM for Excellent Results

What Is Rapid Tooling?

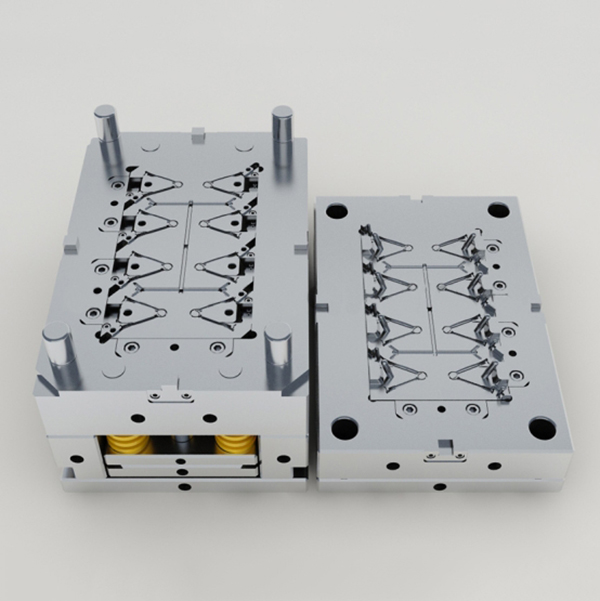

Rapid tooling is often referred to as prototype tooling, bridge tooling, or soft tooling. Rapid tooling is a crucial step on the path to production. It involves the manufacture of tools used to create products, such as rapid injection molds, rapid die cast molds, sheet metal prototype molds, quick and easy jigs and fixtures, and other custom parts.

Therefore, creating rapid tooling to conduct trial production of hundreds or even thousands of parts before mass production is a very useful process for design optimization, functional testing, or pre-production verification.

Rapid Tooling Services

Get high-quality rapid tooling solutions for your prototypes and low-volume productions. SHD combines engineering capabilities with advanced technology to quickly create injection mold tooling at competitive prices.

Common Types Of Rapid Tooling

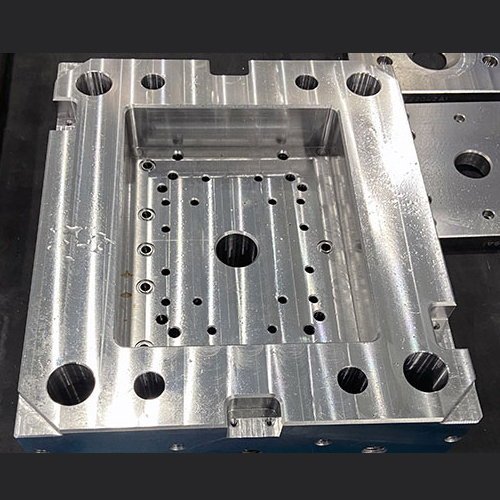

Aluminum Mold Tooling

This is the ideal choice for prototype injection molding because it is a cost-effective means of producing injection molded parts. Using aluminum ensures dimensional stability in the mold tooling, significantly reducing waste production and part deformation during production. Aluminum molds are also easier to cut, thereby reducing tooling costs by up to 25%. Using aluminum molds also reduces cycle times by 30-40%. All of these combine to ensure faster turnarounds.

Steel Mold Tooling

Steel is a high-quality, solid, and sturdy material with a longer life cycle. It is more suitable for high-volume production runs and for producing molds from engineering-grade plastics. Despite its long life cycle, it is more expensive than aluminum and may require more time to produce mold tooling and prototypes.

Why Choose SHD's Rapid Tooling Services?

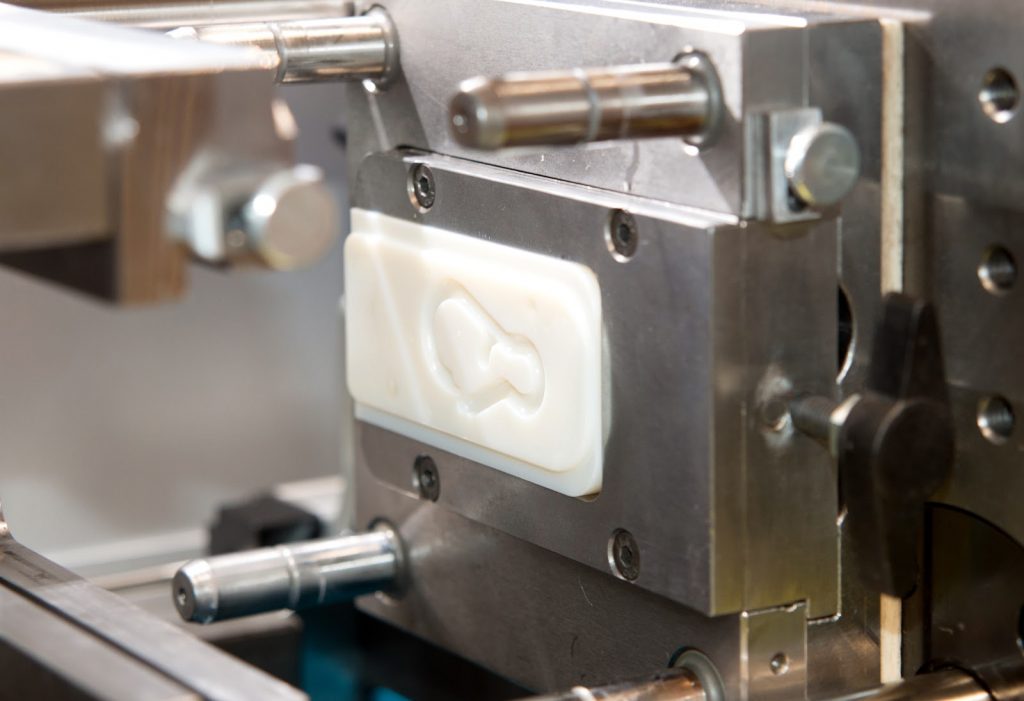

High Efficiency and Quality

Our expertise ensures that we produce high-quality prototype injection molding tools that are close to or 100% match the final production level. We deliver the right tools with mass production quality.

Competitive Prices

Our expert engineers combine advanced techniques with the right materials to give cost-effective solutions. With a better knowledge of rapid tooling designs and material selection, we ensure high-quality molds at the lowest possible price.

Design for Manufacturing Support

As part of prototype injection molding process, we offer design for manufacturing (DFM) support to reveal any issues with your design. Thus, you can make the required changes before prototyping or production begins. This will help save costs.

Timely Delivery

The right combination of technologies and experience results in faster production of prototypes for functional testing. The speed reduces the time you will spend in the prototyping stage, ensuring faster time to market.

Reliable Process

Every one of our projects begins with extensive material testing for optimum performance. Therefore, you can be sure of the composition and integrity of the materials used. We then combine industry-leading technologies to ensure 100% satisfaction with our rapid tooling service.

One-stop Machining Capabilities

Combined with rapid prototyping in CNC machining, EDM machining, 3D printing, vacuum casting and finishing experiences in product development, SHD Precision Tech can produce rapid production tooling and rapid injection mold quickly and efficiently.