Rapid Tooling Parts For 3C Products

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- depends on the product

One-stop Tooling Solutions

Cost-effective and Fast Turnaround

Free DFM for Excellent Results

Rapid Tooling Services

Get high-quality rapid tooling solutions for your prototypes and low-volume productions. SHD combines engineering capabilities with advanced technology to quickly create injection mold tooling at competitive prices.

Why Choose SHD's Rapid Tooling Services?

High Efficiency and Quality

Competitive Prices

Design for Manufacturing Support

Timely Delivery

Reliable Process

One-stop Machining Capabilities

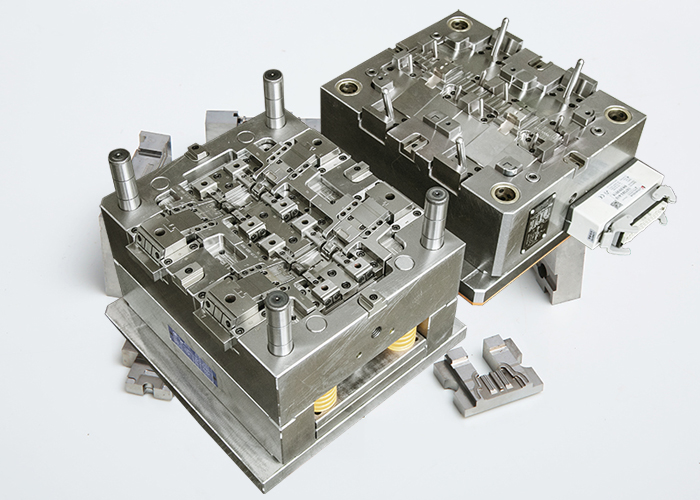

Rapid Tooling & Prototype Injection Molding Services

PART V:How Does Injection Mold Tooling Work?

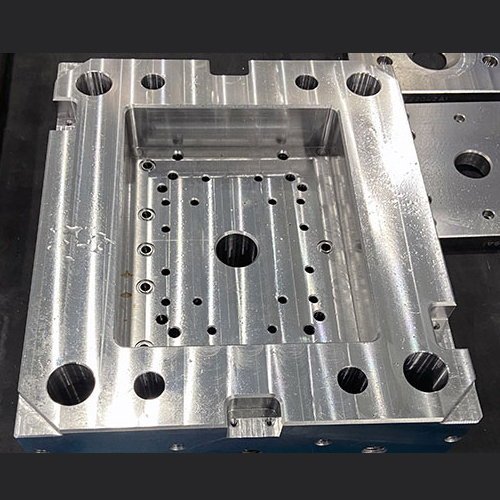

Choose the Right Material of Mold Tools

The right material for mold tools will involve considerations such as intended use, volume requirements, design complexity, and mold structure. Not sure which tooling materials to choose? SHD Precision Tech will help you weigh each of these advantages to find the best rapid tooling solution for your product needs.

We can make rapid mold tools from Aluminum 7075, P20, and NAK80 semi-hardened steels and H13 fully-hardened steel. In addition, we also offer standard SPI finishes, EDM texturing, and a range of etched textures including Mold-Tech® MT series and VDI® 3400 series.

Rapid Tooling Manufacturing Process

In order to fully satisfy the need for rapid production and low-cost reduction, normally we utilize the Master Unit Die Quick-Change (MUD) System which is proven to save rapid tooling process time and reduce costs. Even more importantly, engineering changes involve only the MUD mold insert, not an entire standard mold base. You can also group several similar parts together on what is known as a family tool for greater savings. In addition, manual or semi-automatic inserts are also often used in rapid mold tooling.