Injection Molding

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- depends on the product

Professional equipment and experienced technician contribute to exceptional service.

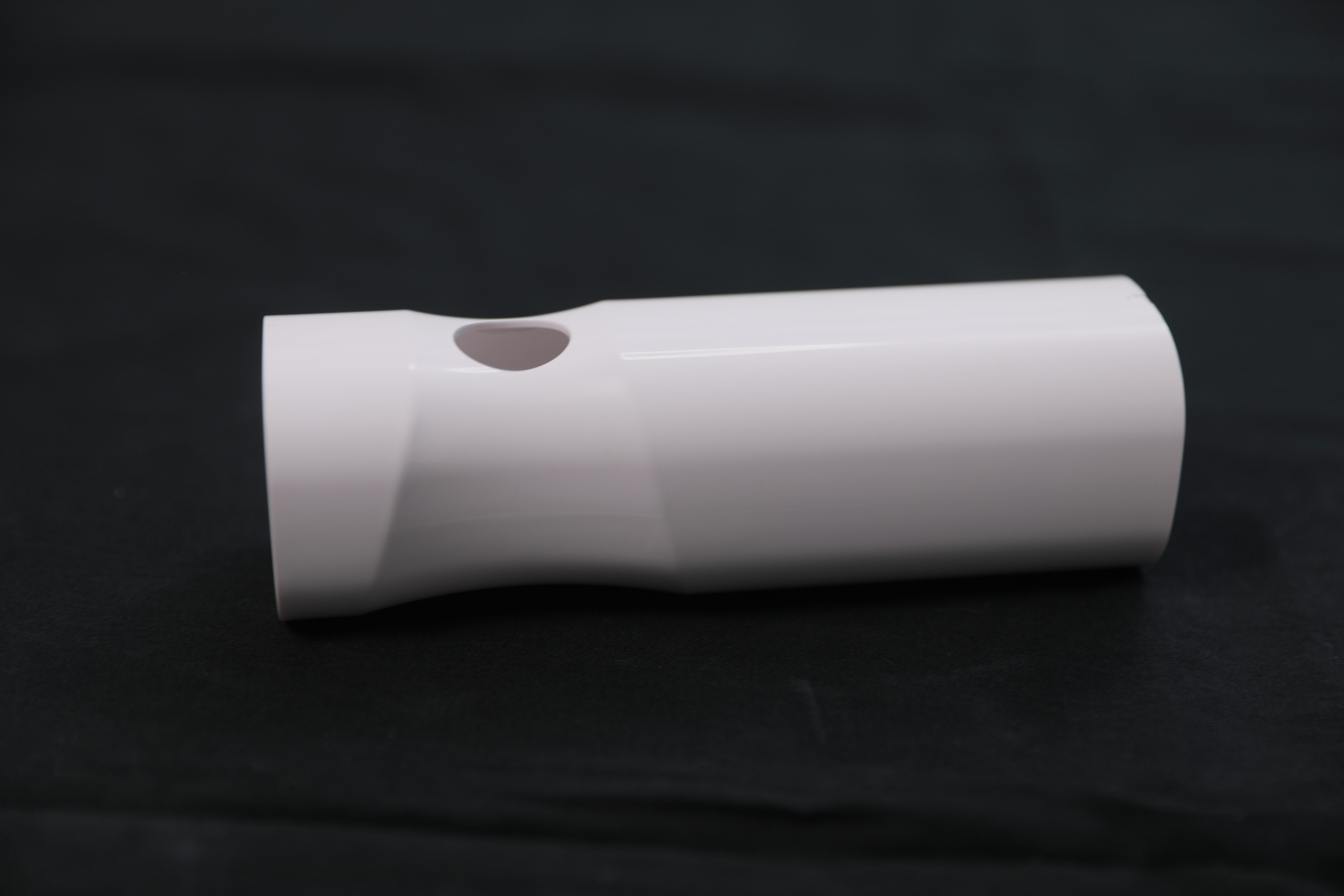

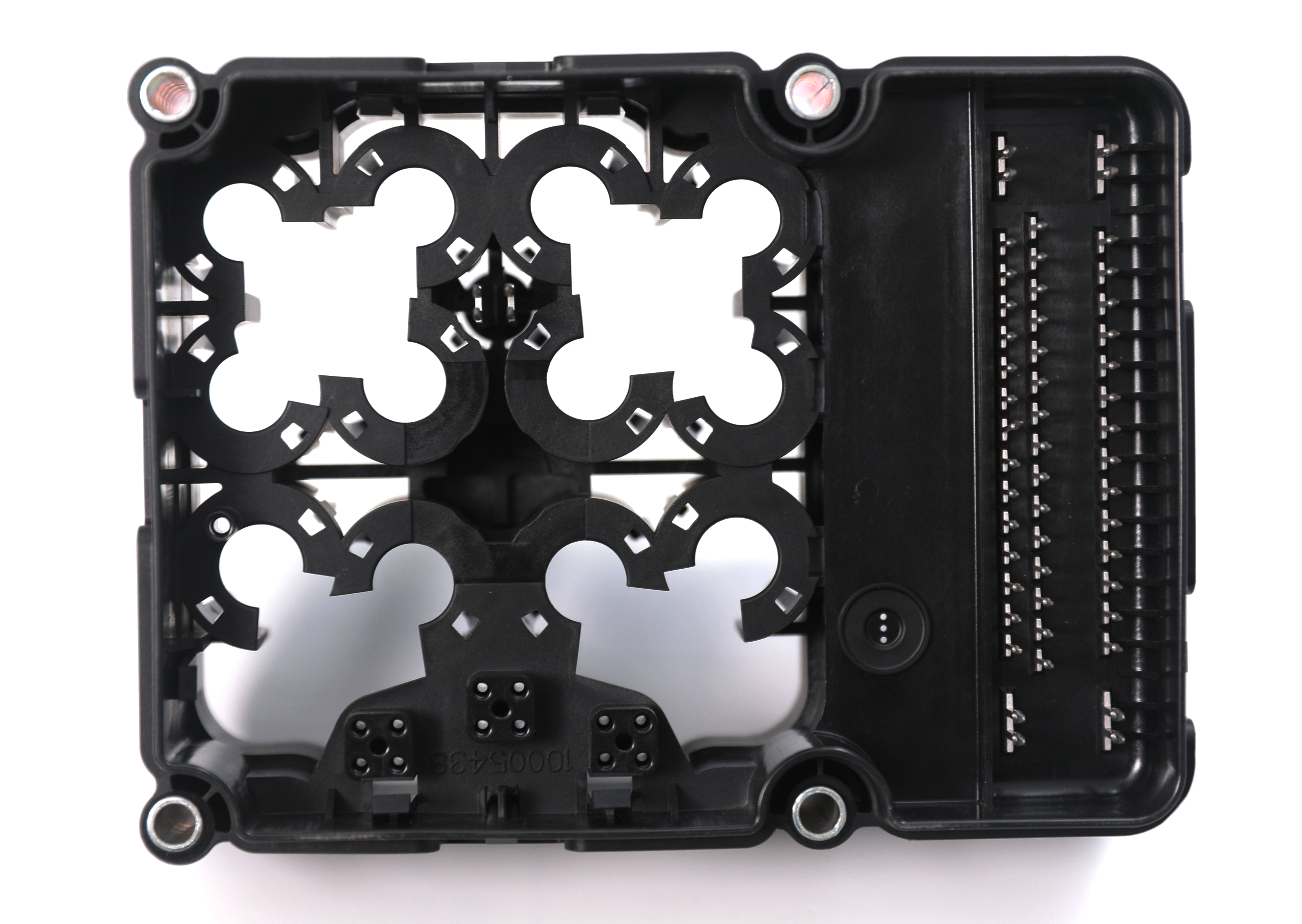

SHD Precision Tech now has 13 sets (35-1600 tons) injection molding machines, main processing in automotive interiors and exteriors, also medical parts, garden and home appliance parts. The main products are:

Automotive: bumpers, bumper garnish, instrument panels, headlights, light transmission bars, fenders, switch panels and brackets, etc.

Gardening: mower engine cover, lawn mower wheel covers, etc.

House appliances: Air conditioning grille, medical car grille, washing machine shell.

Major customers include: CAPSA, Toyota, Honda, Nissan, GAC Mitsubishi and Yanfeng Plastic Omnium, etc..

Production Capacity | 200 sets/year |

Largest Mold Size | 1200 mm ✖ 1700mm |

Maximum Mold Weight | 15T |

Injection Molding Machines | 13 sets(35T—1600T) |

SHD Precision Tech now has 13 sets(35-1600 tons) injection molding machines, such as Toshiba, Haitian, TAYU, AGCO,etc.. Each injection molding machine is equipped with a robot arm and the corresponding cooling machine, mold temperature controller and other ancillary equipments to ensure automatic production and the stability of product qualities.