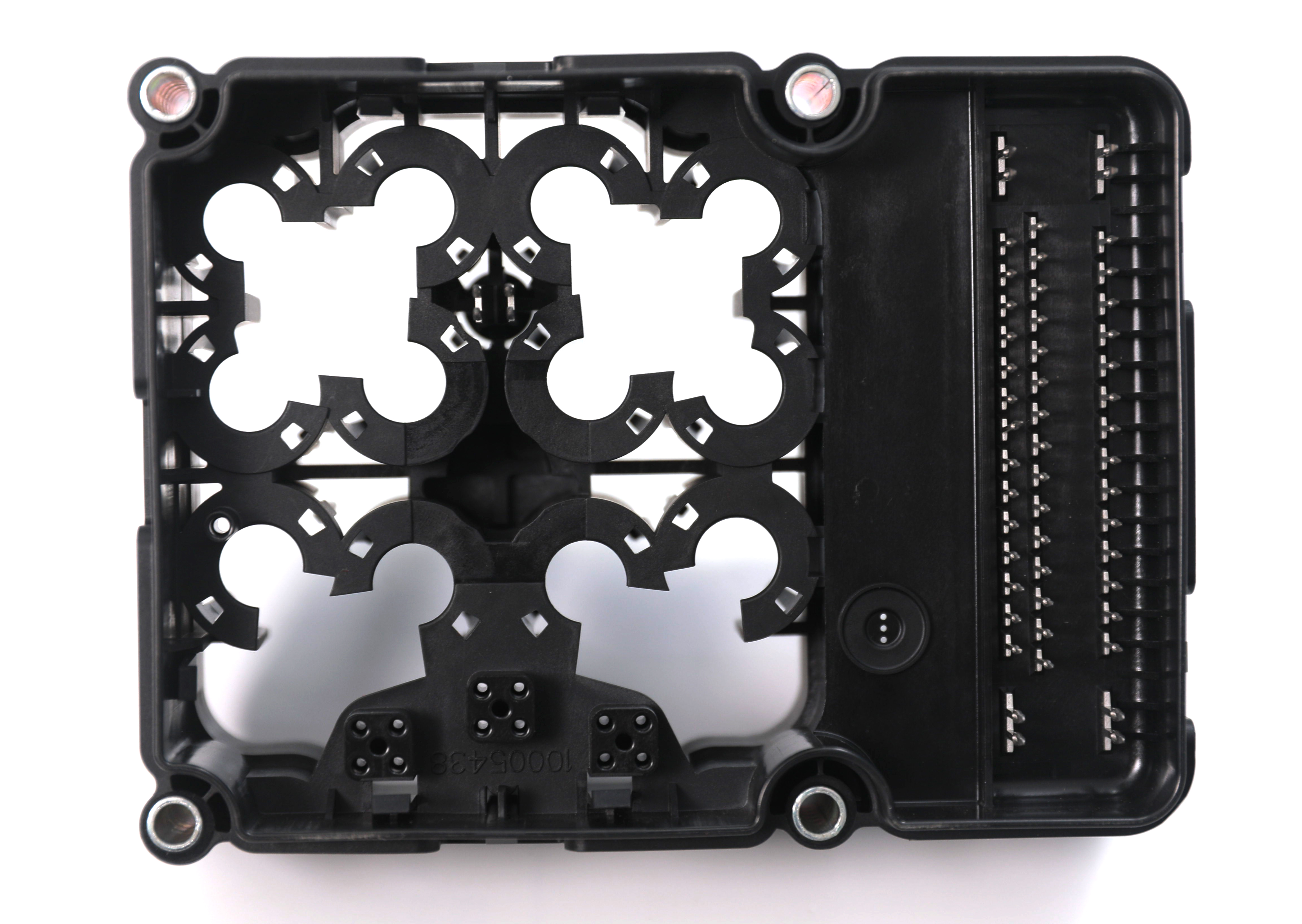

Customized Injection Molding Parts

- SHD Precision Tech

- Shenzhen

- 2 Weeks

- 5000 pcs / month

One stop shop ability and innovative team to provide the excellent customized service.

Injection Molding Service

SHD Precision Tech now has 13 sets (35-1600 tons) injection molding machines, main processing in automotive interiors and exteriors, also medical parts, garden and home appliance parts. The main products are:

Automotive: bumpers, bumper garnish, instrument panels, headlights, light transmission bars, fenders, switch panels and brackets, etc.

Gardening: mower engine cover, lawn mower wheel covers, etc.

House appliances: Air conditioning grille, medical car grille, washing machine shell.

Major customers include: CAPSA, Toyota, Honda, Nissan, GAC Mitsubishi and Yanfeng Plastic Omnium, etc..

Custom injection molding services for plastic prototypes and on-demand production parts. Get a free injection molding quotation and design feedback within hours.

No minimum order quantities

Rapid Tooling Production as fast as 2 weeks

ISO 9001:2015 certified

24/7 engineering support

From plastic prototyping to production molding, SHD Precision Tech's custom injection molding service is ideal for the manufacturing of competitive pricing, high-quality molded parts in a fast lead time. Strong manufacturing facilities with powerful, precise machines ensure the same mold tool for creating consistent parts. Better yet, we provide free eThese are commonly molded plastics that our injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right injection molding material depending on your application requirements.e, materials & surface finishes selection for your end-use applications, and shipping methods.

Materials for Injection Molding

These are commonly molded plastics that our injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right injection molding material depending on your application requirements.

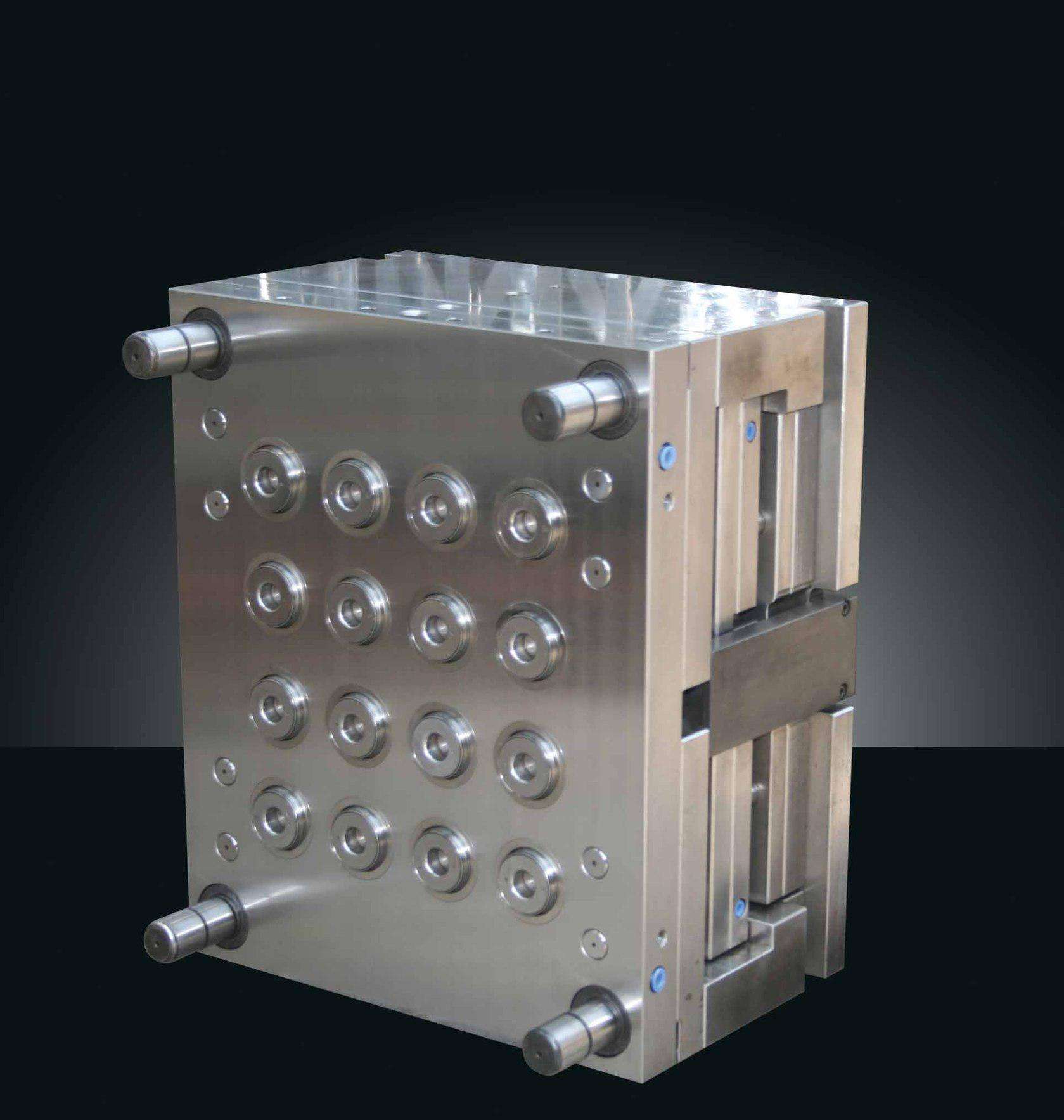

1. Tooling Materials

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include

Tool Steel | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

Stainless Steel | 420, NAK80, S136, 316L, 316, 301, 303, 304 |

Aluminum | 6061, 5052, 7075 |

2. Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

ABS | Nylon (PA) | PC | PVC |

PU | PMMA | PP | PEEK |

PE | HDPE | PS | POM |

3. Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

UV absorbers | Colorants |

Flame retardants | Glass fibers |

Plasticizers |