Customized SLS 3D Printing Parts

- SHD Precision Tech

- Shenzhen

- 3 Days

- 5000 pcs / month

Shorten Delivery Times.

Build Complex Geometry.

Reduce Manufacturing Costs

Why Choose SHD For 3D Printing Service?

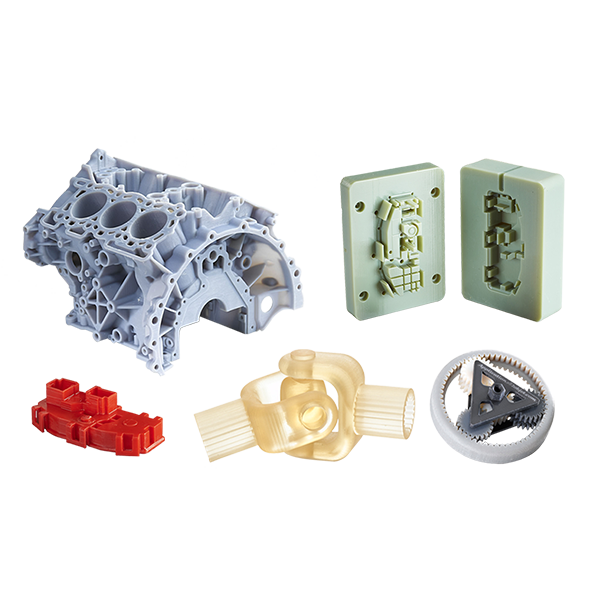

SHD is an expert in the field of rapid prototyping manufacturing in China, providing a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering).

At SHD, We have a full team of dedicated engineers and project managers that will work with you to verify your CAD designs, product functions, dimensional tolerances, etc. As a professional prototype manufacturer, we deeply understand the prototype and production needs of any business. We strive to meet all specified times to deliver products with quality guarantees to our clients worldwide at affordable prices.

Benefits Of 3D Printing

Shorten Delivery Times.

Build Complex Geometry.

Reduce Manufacturing Costs.

What is SLS 3D Printing?

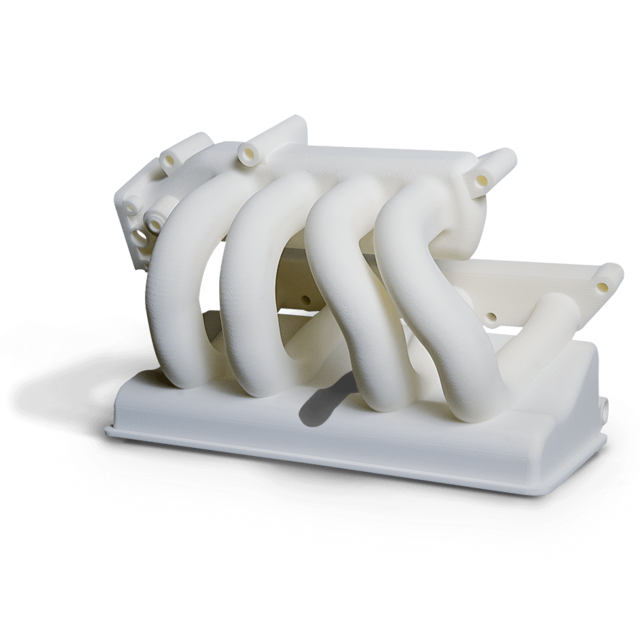

SLS 3D Printing (Stereo Laser Sintering) makes use of a high power optic laser that fuses small powder particles layer by layer to produce complex and durable geometric parts. SLS 3D Printing builds robust parts with filled Nylon materials, suitable for functional prototypes and end-use parts.

How Does SLS 3D Printing Work?

The powder is dispersed in a thin layer on top of a platform inside of the shaped chamber.

When heated just below the melting temperature of the polymer, a laser beam scans the powder according to the cross-section contour of the layer and sinters the power. The unsintered powder supports the cavity and cantilever of the model.

When the sintering of a cross-section is completed, the thickness of the platform decreases by one layer, and the laying roller spreads a layer of uniformly dense powder on it for the sintering of a new cross-section.

The process is repeated until all layers are sintered to obtain the solid model.

Advantages And Applications Of SLS

Advantages of SLS 3D Printing

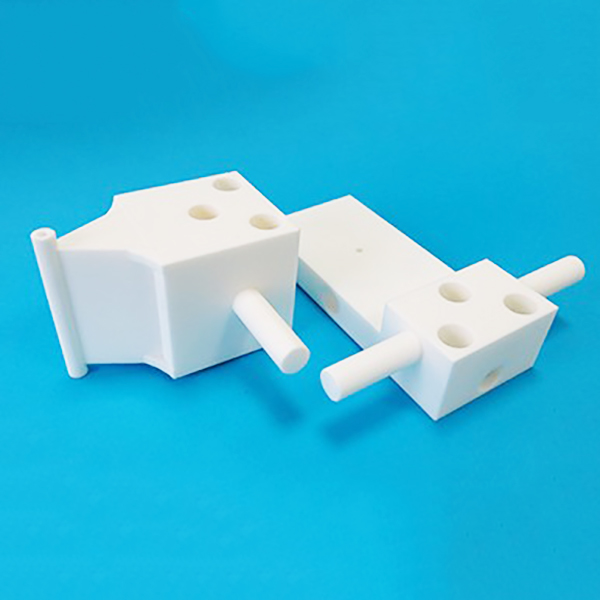

Engineering-grade thermoplastics (Nylon, GF Nylon).

Excellent mechanical properties and layer bonding.

No support structures, enabling complex geometries.

Temperature resistance, chemical resistance, abrasion resistance.

Applications of SLS 3D Printing

Functional Prototypes.

Engineering Test Parts.

End-use Production Parts.

Complex Ducts, Snap Fits, Living Hinges.