3D Printing Parts For Medical Device

- SHD Precision Tech

- Shenzhen

- 3 Days

- 5000 pcs / month

Shorten Delivery Times.

Build Complex Geometry.

Reduce Manufacturing Costs

Why Choose SHD For 3D Printing Service?

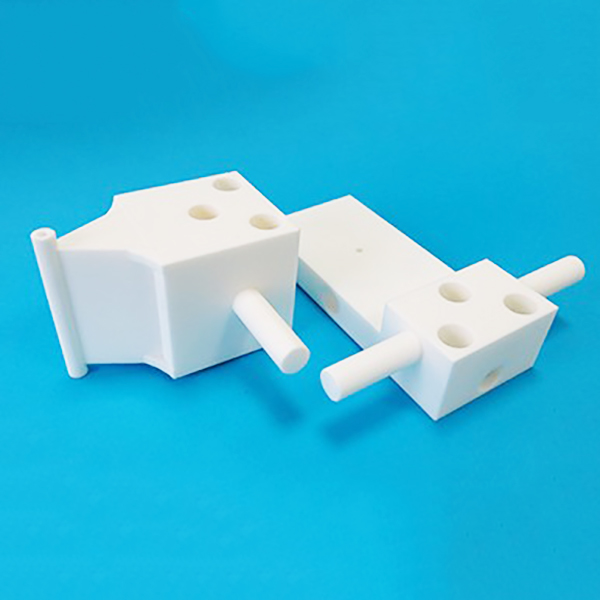

SHD is an expert in the field of rapid prototyping manufacturing in China, providing a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering).

At SHD, We have a full team of dedicated engineers and project managers that will work with you to verify your CAD designs, product functions, dimensional tolerances, etc. As a professional prototype manufacturer, we deeply understand the prototype and production needs of any business. We strive to meet all specified times to deliver products with quality guarantees to our clients worldwide at affordable prices.

Benefits Of 3D Printing

Shorten Delivery Times.

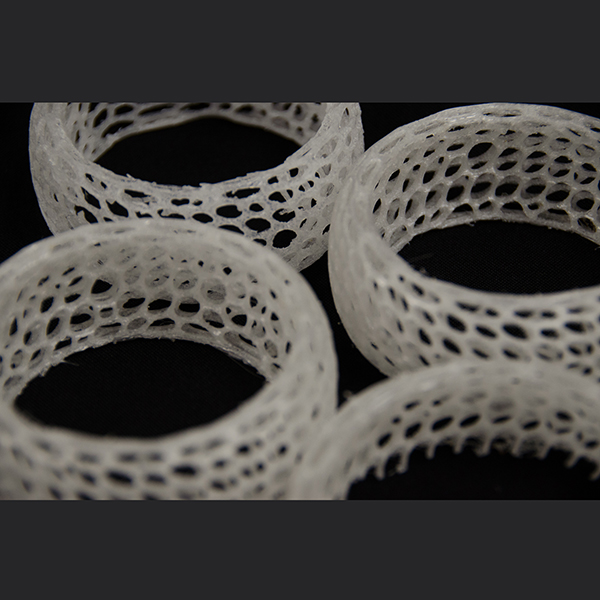

Build Complex Geometry.

Reduce Manufacturing Costs.

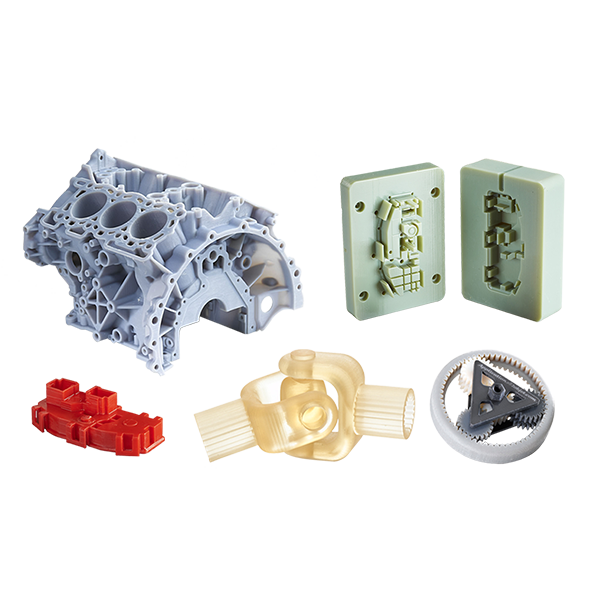

Advantages And Applications Of SLA & SLS

SLA 3D Printing | SLS 3D Printing | |

Advantages |

|

|

Applications |

|

|

3D Printing Vs CNC Machining: Which Is Right For Your Prototype And Production : Part I

Accuracy, Surface Quality & Geometric Complexity

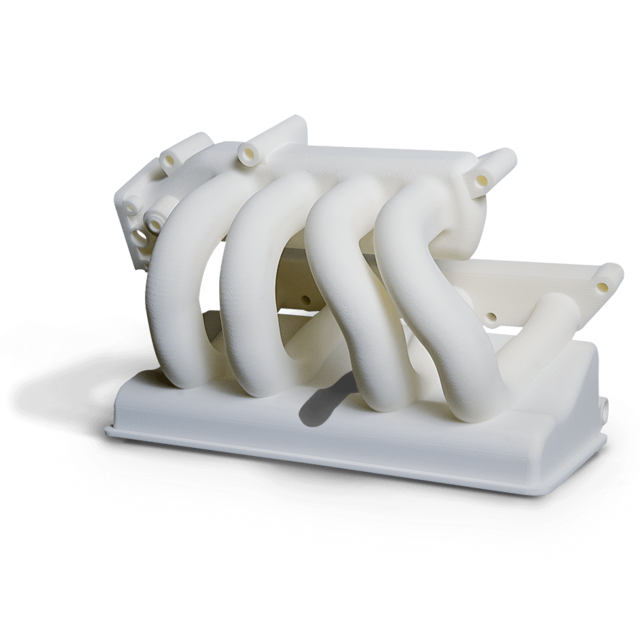

3D printing can create parts with highly complex geometries even hollow shapes that cannot be done by CNC machining, such as jewelry, crafts, etc. CNC machining offers greater dimensional accuracy (±0.005mm) and much better surface finishes (Ra 0.1μm). The advanced 5-axis CNC milling machines can perform high-precision machining of more complex parts that will help you meet your most difficult manufacturing challenges.Cost, Quantity & Delivery Time

3D printing typically produces low quantities of parts without tooling, and without human intervention, so that fast turnaround and low cost are possible. The manufacturing cost of 3D printing is priced based on the number of materials, which means that the larger parts or more quantities cost more. The process of CNC machining is complex, it requires specially trained engineers to pre-program the processing parameters and processing path of parts, and then machining according to the programs. Manufacturing costs are therefore quoted taking the extra labor into account. However, CNC machines can continuously run without human supervision, making them perfect for larger volumes.