3D Printing Parts For Robots

- SHD Precision Tech

- Shenzhen

- 3 Days

- 5000 pcs / month

Shorten Delivery Times.

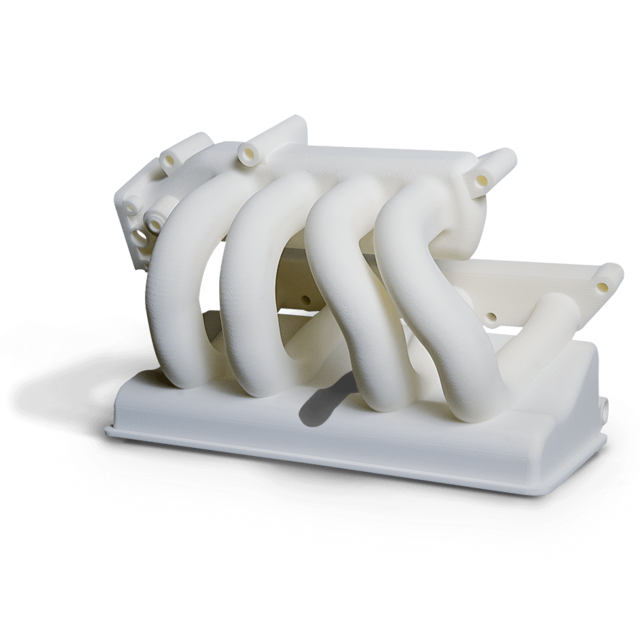

Build Complex Geometry.

Reduce Manufacturing Costs

Why Choose SHD For 3D Printing Service?

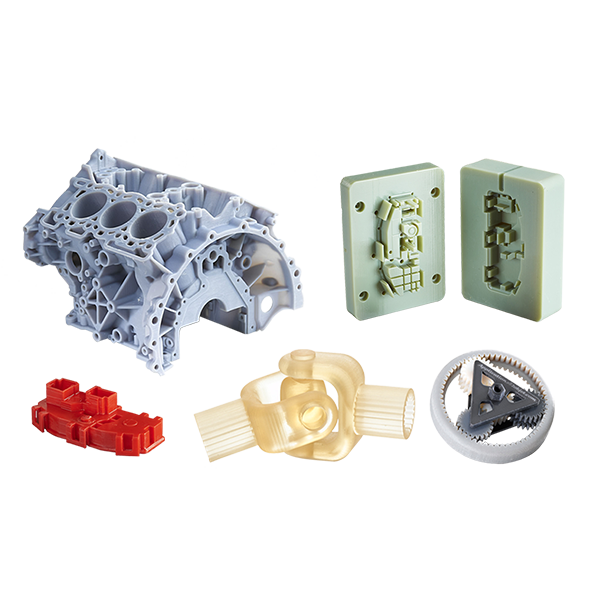

SHD is an expert in the field of rapid prototyping manufacturing in China, providing a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering).

At SHD, We have a full team of dedicated engineers and project managers that will work with you to verify your CAD designs, product functions, dimensional tolerances, etc. As a professional prototype manufacturer, we deeply understand the prototype and production needs of any business. We strive to meet all specified times to deliver products with quality guarantees to our clients worldwide at affordable prices.

Benefits Of 3D Printing

Shorten Delivery Times.

Build Complex Geometry.

Reduce Manufacturing Costs.

Advantages And Applications Of SLA & SLS

SLA 3D Printing | SLS 3D Printing | |

Advantages |

|

|

Applications |

|

|

Compare The Following Capabilities Of SLA And SLS To Choose The Right 3D Printing Service : Part I

Resistance to the Environment

The resistance of SLS 3d printing prototypes to the environment (temperature, humidity, and chemical corrosion) is similar to that of thermoplastic materials; SLA 3d printing prototypes are susceptible to moisture and chemical erosion, and in more than 38 ℃ environments they will become soft and deform.Mechanical Processing Performance

SLS 3D printing uses actual thermoplastic materials to produce parts with good mechanical properties. SLS is more easily processed, and can be easily milled, drilling, and tapped while machining SLA 3D printing should be handled with care in case the part is broken.Dimensional Accuracy

For SLA 3D printing, Minimum Wall Thickness = 0.02” (0.5mm); Tolerances = ±0.006” (0.15mm) to ± 0.002” (0.05mm). For SLS 3D printing, Minimum Wall Thickness = 0.04” (1.0mm); Tolerances = ± 0.008” (0.20mm) to ± 0.004” (0.10mm). SLA 3D printing can build in high resolution with a finer laser beam diameter and finer layer slices to improve details and accuracy.