3D Printing Parts For Industrial Design

- SHD Precision Tech

- Shenzhen

- 3 Days

- 5000 pcs / month

Shorten Delivery Times.

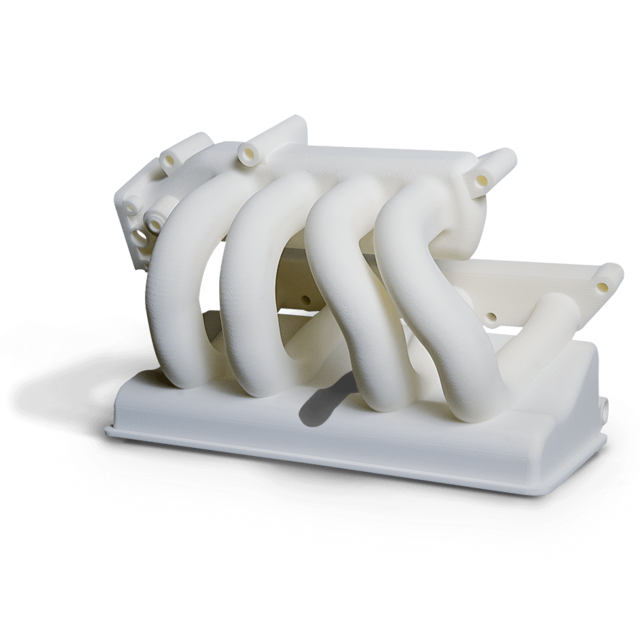

Build Complex Geometry.

Reduce Manufacturing Costs

Why Choose SHD For 3D Printing Service?

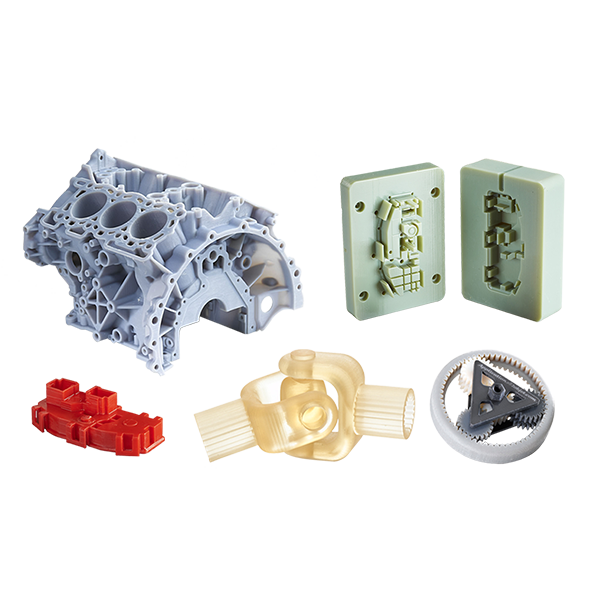

SHD is an expert in the field of rapid prototyping manufacturing in China, providing a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering).

At SHD, We have a full team of dedicated engineers and project managers that will work with you to verify your CAD designs, product functions, dimensional tolerances, etc. As a professional prototype manufacturer, we deeply understand the prototype and production needs of any business. We strive to meet all specified times to deliver products with quality guarantees to our clients worldwide at affordable prices.

Benefits Of 3D Printing

Shorten Delivery Times.

Build Complex Geometry.

Reduce Manufacturing Costs.

Advantages And Applications Of SLA & SLS

SLA 3D Printing | SLS 3D Printing | |

Advantages |

|

|

Applications |

|

|

Compare The Following Capabilities Of SLA And SLS To Choose The Right 3D Printing Service : Part II

Material Properties

SLS 3D printing is rich in materials and can be made of plastic, metal, ceramic, or glass powders with good performance. SHD Precision Tech machines can produce parts in white Nylon-12 PA650, PA 625-MF (Mineral Filled) or PA615-GF (Glass Filled). However, SLA 3D printing can only be a liquid photosensitive polymer, and its performance is not as good as thermoplastic plastic.Surface finish

The surface of the prototype by SLS 3D printing is loose and rough, while SLA 3D printing provides high-definition to make the surface of the parts smoother and the details clearer.Glue Bonding Strength

The SLS 3D printing binding strength is better than that of SLA 3D printing, for which there are many pores on the surface of SLS binding that contribute to the infiltration of viscose.Master Patterns

SLA 3D printing is suitable for the reproduction of the prototype master pattern because it has a smooth surface, good dimensional stability, and fine features.