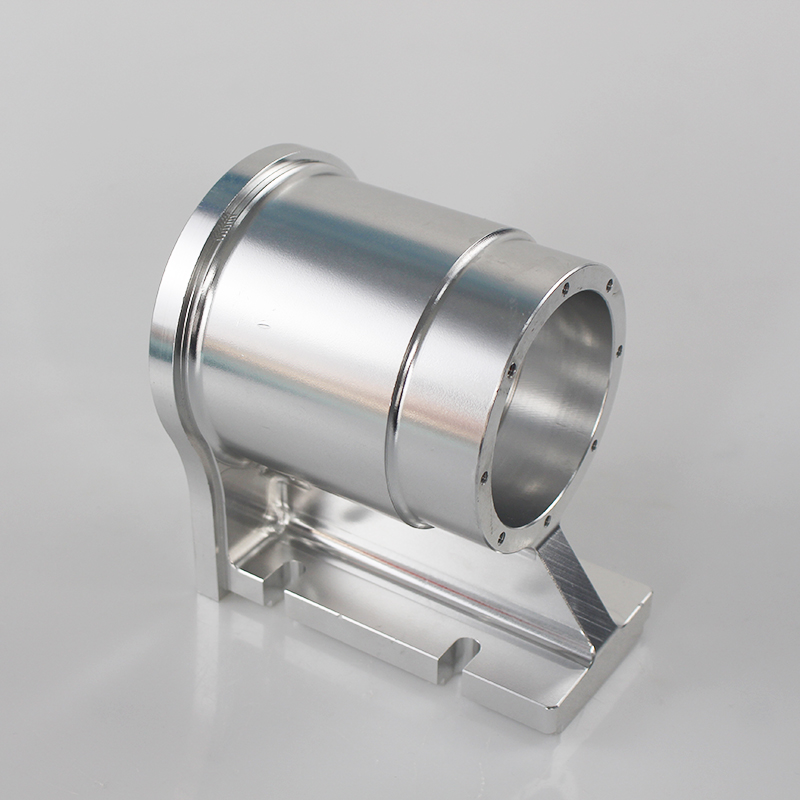

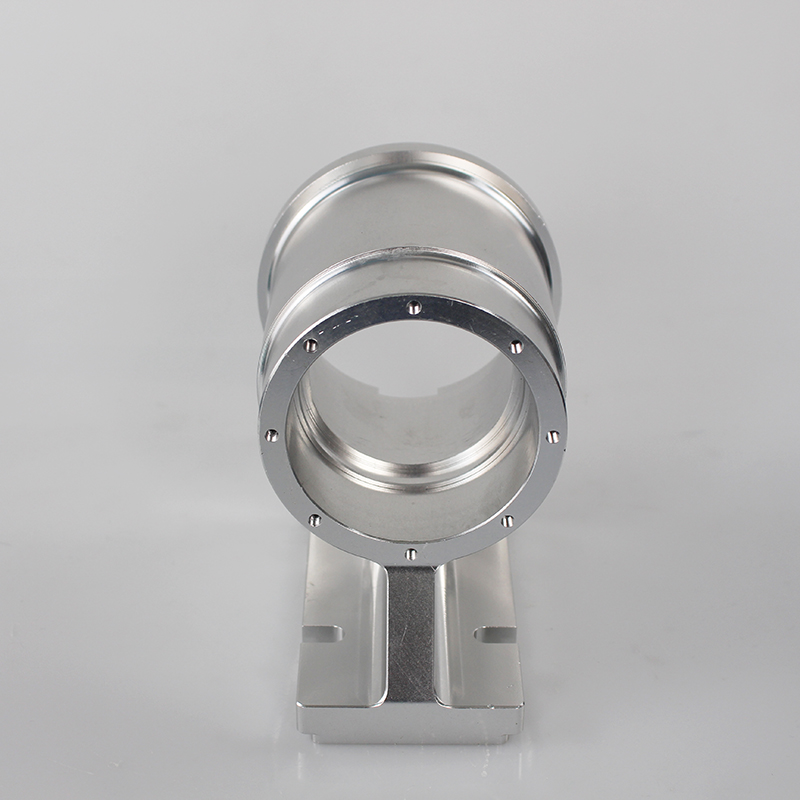

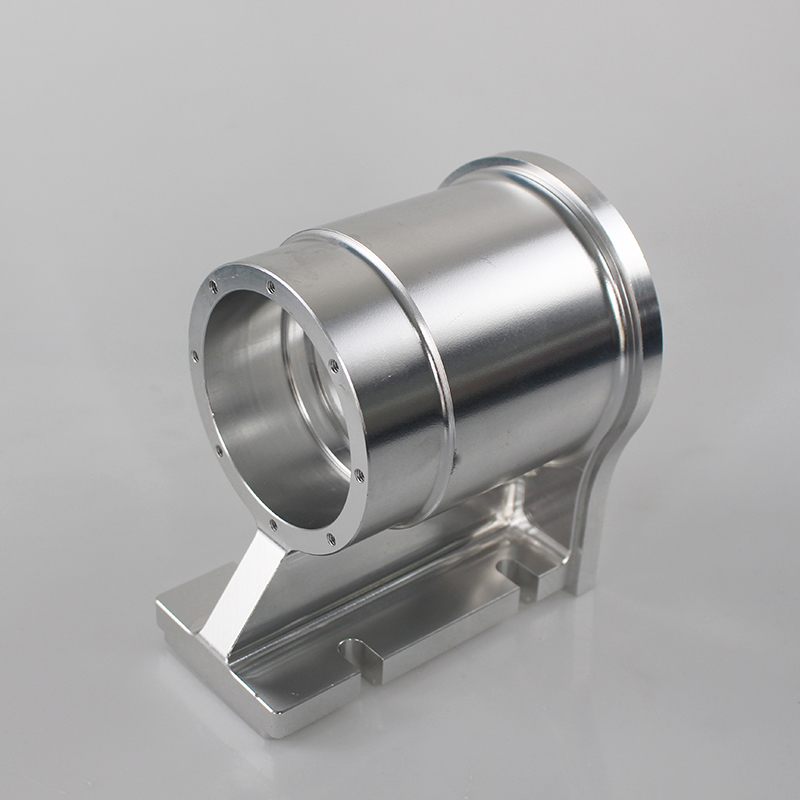

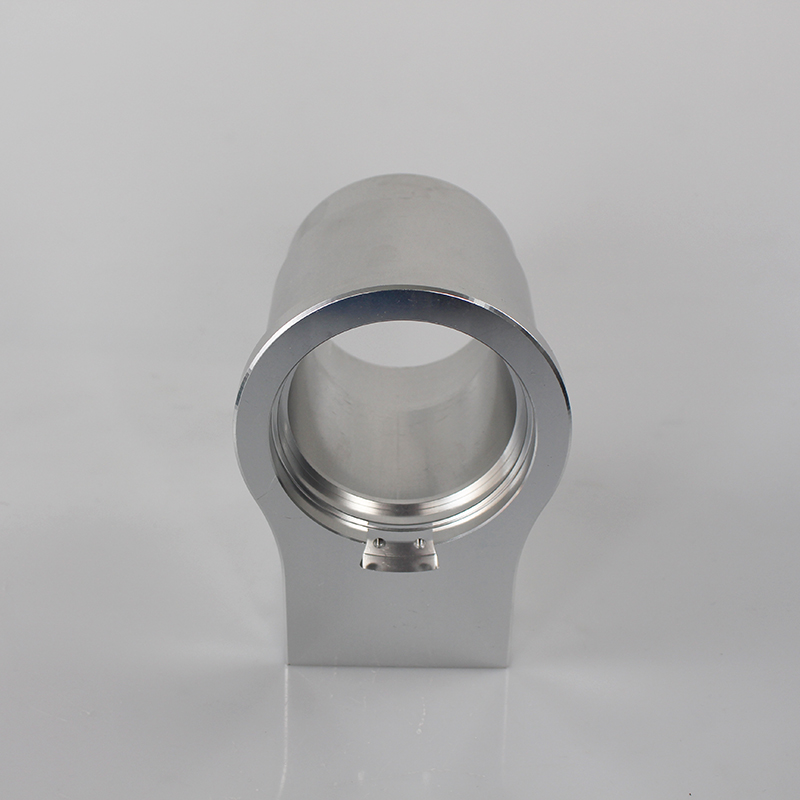

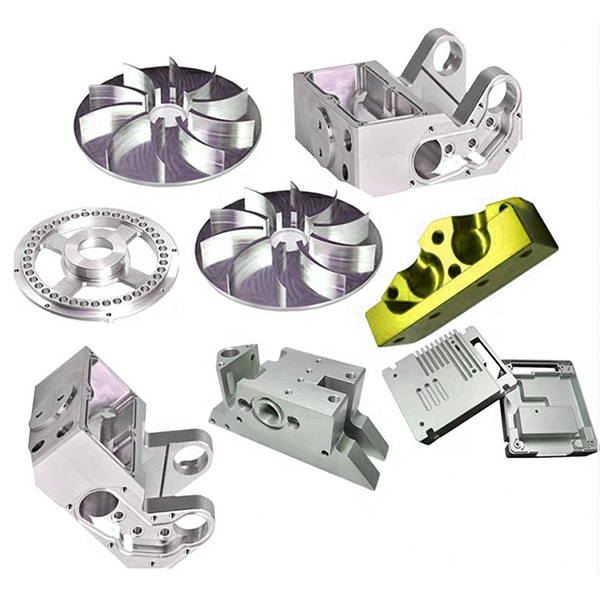

CNC Machining Parts For Medical Device

- SHD Precision Tech

- Shenzhen

- 1 week

- 5000 pcs / month

Faster Delivery

Custom Finishes

High Dimensional Tolerances

Comprehensive Machining Capabilities

Experienced Team

ISO 9001 Certification

Product Details:

Service | CNC Machining Parts For Medical Device |

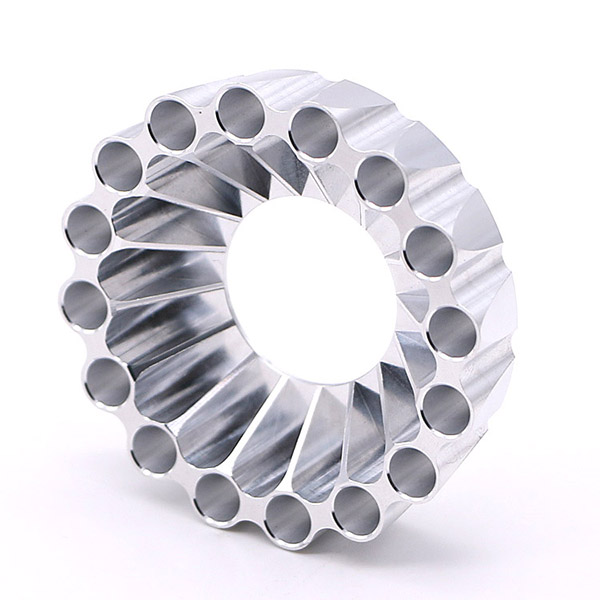

Available materials | Steel, Aluminum, Alloy, Brass, Copper, Bronze, Nylon, Acrylic etc. |

Process | CNC milling, turning, drilling, grinding, bending, stamping, and tapping |

Tolerance | 0.005mm~0.1mm |

Surface Roughness | Ra1.6-3.2 |

DRW format | PDF/DWG/IGS/STP etc. |

Equipment | CNC machining center, CNC turning, General milling machines. |

Capacity | 5,000 pieces per month |

MOQ | 1pcs |

Machining Scope | 1. Equipment/Machinery parts |

QC System | 100% inspection before shipment |

Payment term | T/T, Western Union, Pay Pal |

Surface treatment | Anodizing, zinc/chrome/nickel/silver/gold Plating, Polishing, Heat treatment etc. |

Shipment Terms | 1. 0-100kg: air freight priority 2. >100kg: sea freight priority 3. As per customized specifications |

Packing | 1. Prevent from damage. |

Why Use CNC For Metal Machining?

Eliminate Labor and Reduce Costs

Due to technological developments, machining in the manufacturing industry has been automated. The metal machining process is mainly controlled by computers or robots, which avoids the process of long processes in production lines. Also, it reduces hardware investment and workload, saving a lot of time and effort, and thus reducing production costs.