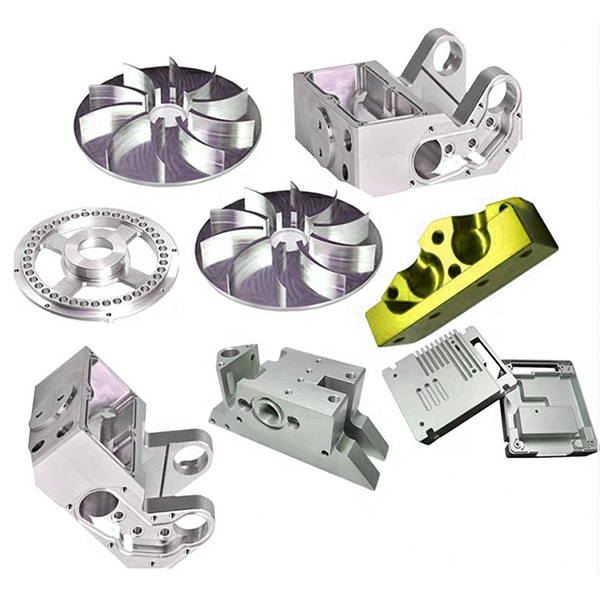

CNC Machining Parts For Industrial Design

- SHD Precision Tech

- Shenzhen

- 1 week

- 5000 pcs / month

Faster Delivery

Custom Finishes

High Dimensional Tolerances

Comprehensive Machining Capabilities

Experienced Team

ISO 9001 Certification

Product Details:

Service | CNC Machining Parts For Industrial Design |

Available materials | Steel, Aluminum, Alloy, Brass, Copper, Bronze, Nylon, Acrylic etc. |

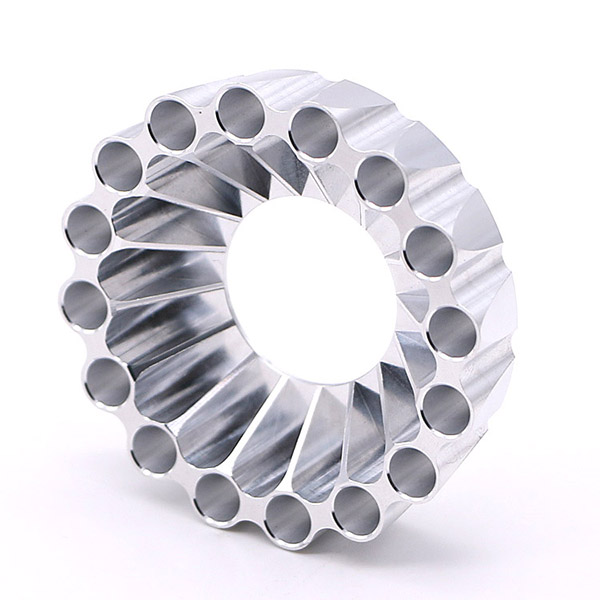

Process | CNC milling, turning, drilling, grinding, bending, stamping, and tapping |

Tolerance | 0.005mm~0.1mm |

Surface Roughness | Ra1.6-3.2 |

DRW format | PDF/DWG/IGS/STP etc. |

Equipment | CNC machining center, CNC turning, General milling machines etc. |

Capacity | 5,000 pieces per month |

MOQ | 1pcs |

Machining Scope | 1. Equipment/Machinery parts |

QC System | 100% inspection before shipment |

Payment term | T/T, Western Union, Pay Pal |

Surface treatment | Anodizing, zinc/chrome/nickel/silver/gold Plating, Polishing, Heat treatment etc. |

Shipment Terms | 1. 0-100kg: air freight priority 2. >100kg: sea freight priority 3. As per customized specifications |

Packing | 1. Prevent from damage. |

How Does CNC Metal Machining Work?

CNC is a high-efficiency automated machine tool for machining complex-shaped workpieces consisting of mechanical equipment and CNC systems. They are equipped with tool storage with an automatic tool change function. Therefore, the workpiece can be multi-process machined after a single set-up.

The CNC system can control the machine tool according to different metal machining operations automatically changing tooling, selecting the spindle speed, feed, etc. So it can be completed continuously by drilling, boring, milling, reaming, tapping, and other processes.

The CNC metal process greatly reduces the workpiece clamping, measuring and machine tool adjustment, and other auxiliary setup time, which is suitable for machining more complex shapes, high precision, and repeatability requirements of the parts.