Analysis of common surface treatment, advantages and disadvantages of precision metal processing

1. Electroplating and electroless plating

Electroplating is to deposit a layer of other metal coating on the surface of aluminum and aluminum alloy by chemical or electrochemical methods, which can change the physical or chemical properties of the surface of aluminum alloy;

Silver plating and gold plating can improve the conductivity of the contact part or the surface;

Copper, nickel or tin plating can improve the weldability of aluminum alloy;

Hot dip tin-plated or aluminum-tin alloy can improve the lubricity of aluminum alloy; precision hardware

Electroless plating refers to the film-forming technology that deposits a metal plating layer on a metal surface by a self-catalyzed chemical reaction in a solution in which a metal salt and a reducing agent coexist. Among them, electroless plating of Ni-P alloy is widely used. Compared with the electroplating process, the surface treatment of metal parts is a relatively low-pollution process. The Ni-P alloy obtained is also a good substitute for chromium plating. However, there are many process equipments for electroless plating, high material consumption, long operation time, complicated procedures, and the quality of the plated parts is not good.

2. Oxidation treatment

The oxidation treatment is mainly anodic oxidation, chemical oxidation, and micro-arc oxidation. In the study of the mechanical properties and corrosion resistance of A356 aluminum alloy, Xu Lingyun et al. performed three different surface treatments on it, including chemical oxidation, anodizing and micro-arc oxidation. Through SEM technology, wear test and corrosion resistance test, the surface morphology, oxide layer thickness, friction resistance and corrosion resistance of aluminum alloy after three kinds of surface treatments were analyzed and compared in detail.

The surface treatment results of the hardware show that after different surface treatments, the aluminum alloy surface can form oxide films with different thicknesses, the surface hardness and friction resistance are significantly increased, and the corrosion resistance of the alloy is also improved to varying degrees.

3. spray paint, baking paint, spray paint, spray porcelain

This is a step that many precision hardware parts manufacturers will perform when processing finished products, especially in some relatively large products. The presence of spray paint not only makes the product less prone to rust, but some special spray paint will also produce some other effects, making the product's performance even better.

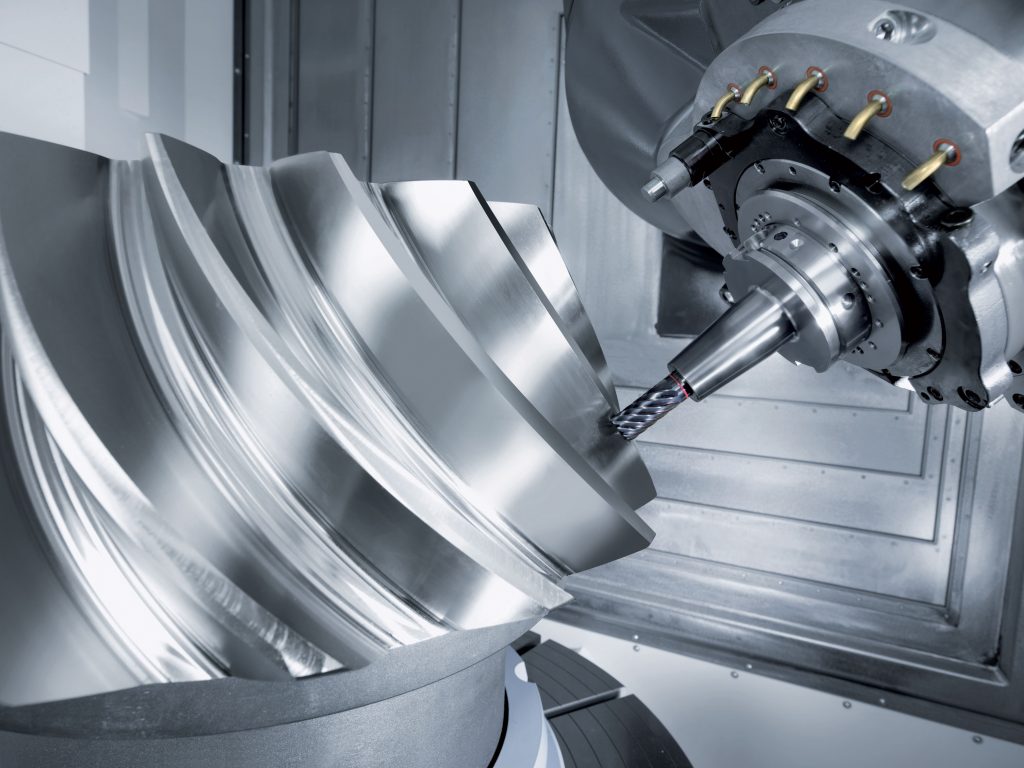

4. polishing, brushed polishing, grinding, shot blasting, shot blasting, vibration grinding

The processing technology of precision hardware accessories is used in some daily necessities, especially in some products that are easy to pilling and burrs. Polishing is a step that must be passed. Not only to maintain the appearance of the product, but also to make the user experience better.

5. overmolding

Metal dipping is a plastic coating process. Dipping is divided into hot dipping and cold dipping according to whether it needs heating. According to the raw materials of dipping, it can be divided into liquid dipping and powder dipping. The corresponding processing It is divided into liquid impregnation processing and powder impregnation processing. The equipment for cold impregnation is generally workshop-style. Because hot impregnation requires long-term heating, general soil-made equipment will have uneven temperature and a slow temperature rise after a few months. For such issues, the dip equipment is divided into manual, semi-automatic and assembly line dip machines, as well as Keguan pipeline coating equipment specially used for pipeline coating.